250ml Bottle Liquid Filling Machine Automatic Piston Filling Capping Labeling Line

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 25 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 25 Sets per Month |

|

Detail Information |

|||

| Filling Range Optional: | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | Voltage: | 220V/110V/380V ( Customizeble ) |

|---|---|---|---|

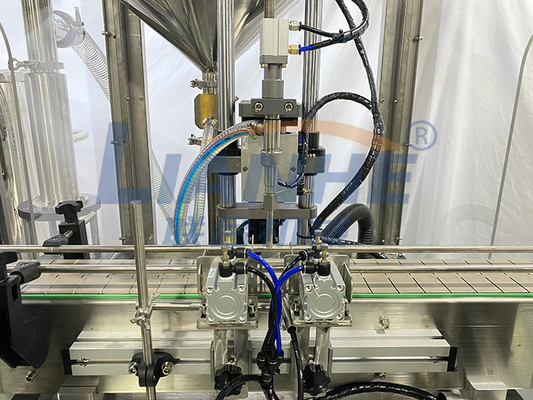

| Filling Nozzle: | 1, 2, 4, 6, 8, 10, 12 Nozzles Optional | Driven Type: | Piston |

| Core Components: | Motor, PLC, Gear, Bearing, Gearbox, Engine | Material: | Rack SUS304 (Material Contact Parts: SUS316) |

| Highlight: | 250ml Bottle Liquid Filling Machine,Automatic Piston Bottle Liquid Filling Machine |

||

Product Description

Automatic Shampoo Detergent Cream Jar Piston Filling Capping Machine

At a glance, you may have considered the process of filling, capping and labelling your shampoo to be simple. All you have to do is pour the content into the bottle and cap it off, no it's not that simple. There's much more to your fascination. Have you ever wondered how exactly your shampoo gets into the bottle, how they capped and get the label? If yes, then this article is for you. Are you ready to learn more about this fascinating process? Let's get started!

Different industries deal with different liquid-content products such as juice, hand wash, detergents, etc, and require liquid-content filling precisely so that each bottle is accurately filled with the exact volume, capped tightly and labelled.

Either they can use manpower or machinery for this purpose. If they use manpower the process will be slow and not accurate so machinery is the best option. To keep the cost down liquid products companies have produced or invested in cheap machinery equipment overtime to fill their orders. The advanced machinery used for filling, capping and labelling is categorised as a filling machine.

LIANHE manufactured a filling capping labelling machine. This machine is mostly used in industries for liquid-content products such as shampoo, gels, juice liquid soap, etc. This machine has a one

year warranty.

This equipment consists of an apparatus of bottle unscrambler, a fully automatic liquid filling machine, a fully automatic capping machine and an automatic labelling machine. This equipment also has a weight checker, PLC control, inkjet printer and ribbon printer.

How does it work?

First of all, all bottles that are meant to be filled whether they are of glass or plastic or any other material placed on the bottle unscrambler apparatus. All the bottles settled and then one by one started moving for their filling. Secondly, a fully automatic filling machine fills the bottles with the content one by one with high filling accuracy. It is designed as an anti-drip. After filling, bottles continue moving where the caps are fed into the bottles. Then with the capping wheels, the fully automatic capping machine capped all the bottles.

After capping, the bottles went to the next machine which is also fully automatic and is a labelling machine. It labels the bottles and after that bottles are deposited into cartons for packaging.

![]()

![]()

![]()

![]()

Why choose us?

LIANHE machinery is a scientific enterprise. We have complete machining equipment, perfect technological flow, powerful technology ability, excellent product development and design ability as well as rich production experience.

By always adhering to the quality policy and service tenet of “insisting on scientific innovation, bringing forward brand strategy, providing high-quality products and implementing first class service”, Lianhe personally is welcoming friends from all circles to visit and instructs us for sincere cooperation and mutual brilliance through our best quality and top-ranking service.