Single Nozzle 380V Liquid Filling Machine Rustproof PLC Control

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, TUV, SGS |

| Model Number: | LH-V10 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 30 Working Days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Sets Per Month |

|

Detail Information |

|||

| Voltage: | 220V/110V/380V Customized As Country | Filling Volume: | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml |

|---|---|---|---|

| Filling Nozzle: | 1, 2, 4, 6, 8, 10, 12, 14 Nozzles | Filling Speed: | 10-100 Bottles/min Customized |

| Control: | SIEMENS PLC Touch Screen | Key Selling Point: | High Accuracy, Stable Performance |

| Highlight: | 380V Liquid Filling Machine,Rustproof Liquid Filling Machine,PLC Single Nozzle Liquid Filling Machine |

||

Product Description

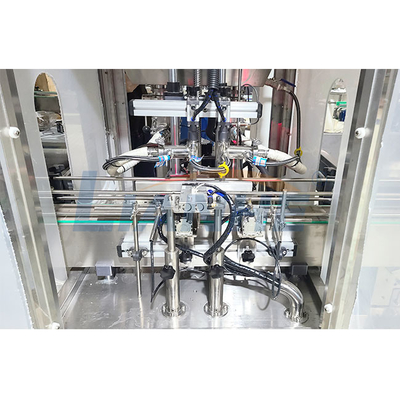

4 Head Liquid Filling Machine L Shape Shampoo Cream Lotion Bottling Line

Product Description:

This filling/capping/labeling line is designed for a cosmetic / skin care factory, which will be filling cream, shampoo, liquid soap, hand sanitizer gel, lotion, etc. But it can also be using for other liquid/paste products, such as mayonnaise, ketchup, wax, etc.

This series of paste filling machine is our company set production experience for many years, and the introduction of absorbing the world advanced technology development and become a new generation of fully automatic filling machine.It uses a piston quantitative, integrating mechanical and electrical, pneumatic, electrical and pneumatic components to choose the world famous brand, controlled by PLC, reasonable design, compact structure, beautiful shape, with stable and reliable performance, high filling precision, strong adaptability, simple operation and convenient maintenance, etc.

Widely used in various semiliquid, paste, viscous body, sauces, and contains a variety of makings of filling material.Such as pulp beverage, honey, syrup, jam, peanut butter, sesame paste, tomato sauce, chili sauce and all kinds of paste.

For more details of this filling line, please contact us for video.

Product Parameters:

Automatic Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

| Filling Nozzle | 1 Nozzle | 2 Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle |

| Filling Speed | 20 bot/min | 25 bot/min | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min |

| Filling Volume | 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V/380V/410V/440V, 60Hz, 3 Phase | ||||||

| Air Consumption | 0.5-0.7Mpa | ||||||

| Remark |

1. The filling speed based on 500ml/bottle water.

2. More options can be customized according to your requirements.

|

||||||

Product Features:

* Adopts PLC and human machine interface technology.

* Match photoelectric tracking switch, integrates electric and pneumatic functions into one.

* With reasonable design, stable performance, accurate quality, glass table surface.

* Automatic bottle feeding, and steady operation without noise.

* Electric speed control to the filling speed and filling volume, convenient maintenance and cleaning.

* The new type filling equipment is the best choice for the realization of automatic production.

* Can connect with bottle feeding table, capping and labeling machine,effective cost / space saving

* It has intuitive and convenient operation, measuring accurate, positioning precision

* Fully in accordance with the GMP standard production and passed CE certification

* Siemens Touch screen/PLC+anti explosion pump+Servo motor control

* No bottle no filling

Product Application:

![]()

Product Advantages:

Highly precised piston pump

Piston pump filling nozzle

6 head filling (filling nozzle can be customized to 1/2/4 /6/10/12/14)

Filling nozzle made of SS316L

304/316 Stainless steel high precision filling nozzle.

Filling volume adjustable in fine rank, same liquid level after filling.

All 304/316 stainless steel contact parts & liquid tank, fine polish, no death corner, easy to clean.

304/316 stainless steel filling pump

PLC Control System

Imported brands for PLC touch screen control system, high class appearance, easier and faster for operation. Filling

ANTI-DROP Filling Nozzles: 2/4/6/8/10/12 heads

Equipped with SUS316L long special designed no-drop filling nozzles, which can protect the cylinder on the top being damaged material; Design different size of filling nozzles

SERVO MOTOR Control Filling Volume

SUS304 frame, Round SUS316L PISTONS,TECO servo motor control, easy to adjust the volume, just need to input the volume needed in touch screen

Product Details:

1. Use automatic volumetric piston pump executive filling, it is applicable for various viscosity liquid ,high precision; fast disassembly institutions of pump, easy to clean and disinfect.

2. PLC control system, frequency control, high degree of automation.

3. No bottles not filling automatic counting functions.

4. Filling capacity is easy to adjust, all metering pump filling quantity can be adjusted one time, can also be aimed at each pump on micro-measurement adjustment. Simple operation and quick adjustment.

5. Filling head equipped with pneumatic drip tight device.

6. The machine can be used for various specifications of bottles, adjust the simple, can be finished in a short time.

![]()

![]()

![]()

![]()

Our Servers:

-

Warranty: One year since the date of installation. If there is any wearing parts be within the warranty and isn’t caused by un-proper operation, Lianhe will offer new parts for free.

-

Inspection: Buyer could visit our factory for site inspection, we could also send some machine testing videos to buyer if buyer couldn't come.

-

Machine Installation or Fixing: On site installation is available, Lianhe can send 1-2 technicians to buyer's factory for installation, testing and training. We can also provide online installation guidance instead, and provide you some 3D videos, instruction videos if buyer prefer installing by themselves.

-

Lifetime maintenance assistance and online video call service.