Automatic 6 Nozzle High Precision Piston Hand Washing Filling Capping Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 25 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 25 Sets per Month |

|

Detail Information |

|||

| Material: | SUS 316L & 304 | Filling Range: | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml |

|---|---|---|---|

| Voltage: | 220V / 380V Customized | Filling Accuracy: | ±0.1% |

| Driven Type: | Servo Piston System | Application: | Chemical , Food ,Pharmaceutical |

| Highlight: | Automatic Hand Washing Filling Capping Machine,6 Nozzle Filling Capping Machine |

||

Product Description

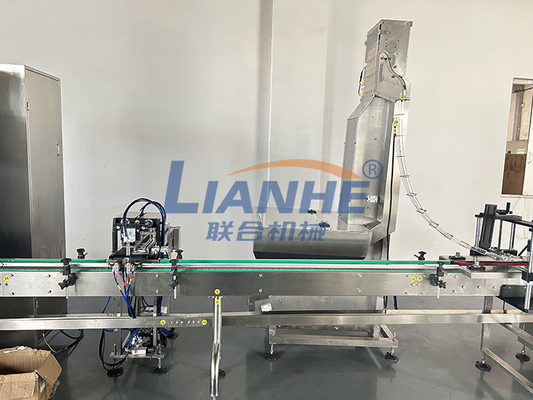

Automatic 6 Nozzle High Precision Piston Hand Washing Filling Capping Machine

Product Description:

This filling machine adopts PLC and human-machine interface technology. Match photoelectric tracking switch. The machine integrates electric and pneumatic functions, reasonable design, stable performance, accurate quality, glass table, automatic bottle loading, smooth operation without noise, electric speed regulation of filling speed and filling volume, and convenient maintenance and cleaning. The new filling equipment is the best choice for automatic production.

Product Application:

The automatic liquid filling capping and labeling machine is used to filling, cap screwing and label stikering of liquid products, such as liquid soap, detergent, cream, lotion, etc. The automatic line is suitable for most shape of bottles and caps.

![]()

Product Parameters:

| Filling Nozzle | 1 Nozzle | 2 Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle |

| Filling Speed | 10 bot/min | 25 bot/min | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min |

| Filling Volume | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V/380V/410V/440V, 50/60Hz, single Phase | ||||||

| Air Consumption | 0.5-0.8 Mpa | ||||||

| Remark |

More options can be customized according to your requirements.

|

||||||

Main Features:

1. High degree of automation, simple operation, stable operation, can effectively save enterprise costs, improveproduction efficiency.2. Each stand-alone machine can complete its work independently. It has independent operating system, digitacontrol display and other electrical components to control and adjust various parameters and display settings. It canhelp enterprises realize standardized production3. The single machine linkage. separation fast, and adjust fast, simple. so that each production process to ensurecoordination.

4. Each stand-alone machine can adapt to the packaging of various specifications of bottles with few adjusting

parts.5. The packaging production line adopts the international new process design, in line with GMP standards.6.The production line runs smoothly, the combination of various functions is convenient, and the maintenance isconvenient

Product Details:

1. Filling Nozzles: 1/2/4/6/8/10/12 Customizable no-drop filling nozzles. Different sizes to fit different bottles, easy to be assembled.All the material contact part is made of stainless steel 316L.

2. Various Filling Range: 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml. With adjustable speed conveyor belt, and high strength stainless steel frame, firm and wear-used.

3. Servo Piston Motor: Servo motor control filling, higher filling accuracy and more stable performance.

4. PLC Control System: PLC touch screen control system, high class appearance, easier and faster for operation.

![]()

![]()

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte