30-60 Bottles/ Min Shampoo Bottle Filler , SUS316L Liquid Soap Bottle Filling Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20-30 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Voltage: | According To Customer | Filling Volume: | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml |

|---|---|---|---|

| Filling Nozzle: | 1, 2, 4, 6, 8, 10, 12 Nozzles | Filling Speed: | 30-60 Bottles/min |

| Material: | SUS 304/316L | Filling Method: | Servo Motor + Piston Filling |

| Highlight: | 30 Bottles/Min Shampoo Bottle Filler,60 Bottles/Min Shampoo Bottle Filler,SUS316L Liquid Soap Bottle Filling Machine |

||

Product Description

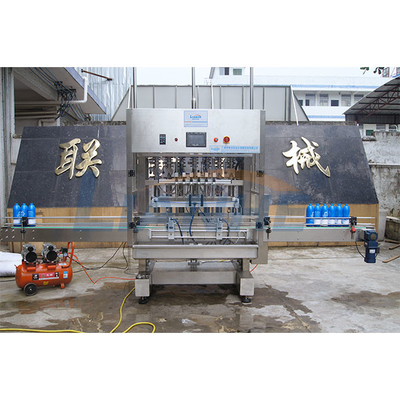

Fully Automatic Liquid Filling Machine Shampoo Shower Gel Filling Machine

Product Description:

High Viscosity Filling Machine is the new-generation improved volumetric filling machine.

The whole machine uses the in-line structure and it is driven by the servo motor. Volumetric filling principle can realize the high precision of filling. It is controlled by the PLC, human interface and easy operation. The machine is equipped with electric scale weight feedback system which makes the volume adjustment easier. it is a nice choice for foodstuff, pharmacy, cosmetic and chemical industries.

Product Parameters:

Automatic Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

| Filling Nozzle | 1 Nozzle | 2 Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle |

| Filling Speed | 20 bot/min | 25 bot/min | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min |

| Filling Volume | 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V/380V/410V/440V, 60Hz, 3 Phase | ||||||

| Air Consumption | 0.5-0.7Mpa | ||||||

| Remark |

1. The filling speed based on 500ml/bottle water.

2. More options can be customized according to your requirements.

|

||||||

Product Features:

1.Touch screen operation ,humanization design ,easy to operate .

2.Micro computer can program PLC control ,easy and convenient to change the type and parameter .

3.Accurate liquid level sensor ,automatic feeding material ,ordinary pressure to fix flow way parameter ,help you to finish accurate filling section .

4.The machine through special design for the lifting institution ,easy and convenient to adjust ,can pack multiple types container . It is different from traditional lifting method ,the traditional lifting make the tube too bend lead to delay filling time .

5.Photoelectric sensor and pneumatic door coordinate control ,lack bottle ,pour bottle all has automatic protection .

6.Pneumatic control valve, effective safety,each flow way has independent adjustment and cleaning .

7.Freely setting filling volume through touch screen .

8.Adopt none-drip and none-silk filling nozzle institution design .

9.Main body material is SUS 304 and through anode dispose aluminum alloy, contact part is SUS 316L.

Product Advactage:

A) PLC and Touch screen full automatic control. Easy for operate

B) Fastly different bottle size replacement

C) Concise structure, reliable and durable, easy to maintain.

Product Details:

1. Filling Nozzles: 1/2/4/6/8/10/12 Customizable no-drop filling nozzles. Different sizes to fit different bottles, easy to be assembled.All the material contact part is made of stainless steel 316L.

2. Various Filling Range: 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml. With adjustable speed conveyor belt, and high strength stainless steel frame, firm and wear-used.

3. Servo Piston Motor: Servo motor control filling, higher filling accuracy and more stable performance.

4. PLC Control System: PLC touch screen control system, high class appearance, easier and faster for operation.

![]()

![]()

![]()

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte.