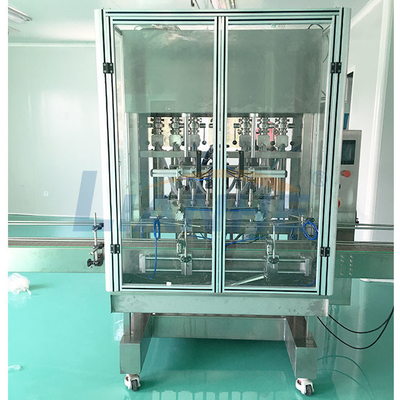

SUS304 Shampoo Automatic Lotion Filling Machine 6 Nozzles Rustproof

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AF |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20-30 working days |

| Payment Terms: | L/C, T/T |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Voltage: | According To Customer | Application: | Cosmetic, Daily Chemical, Food, Pharmaceutical |

|---|---|---|---|

| Filling Volume: | 5-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | Filling Nozzle: | 1, 2, 4, 6, 8, 10, 12 Nozzles |

| Filling Speed: | 30-60 Bottles/min | Material: | SUS 304/316L |

| Control: | PLC + Touch Screen | Filling Method: | Servo Motor + Piston Filling |

| Highlight: | SUS304 Automatic Lotion Filling Machine,6 Nozzles Automatic Lotion Filling Machine,Rustproof Automatic Shampoo Filling Machine |

||

Product Description

Automatic Liquid Soap Lotion Shampoo Liquid Filling Machine 6 Nozzles

Product Description:

This is a intelligent filling machine ,suitable for filling different materials,no matter high viscosity liquid or non-viscosity liquid. The whole machine is a straight-line mechanism, which uses servo motor to drive filling and volumetric metering to realize high precision of filling dose. Can change bottle types quickly. The biggest feature of this machine is that can be automatically removed cylinder to clean it quickly!

Product Parameters:

Automatic Filling machine is controlled by computer via an auxiliary device (such as a cylinder block bottle system, stop bottles system, lifting system, feeding control, counting devices, etc.) to complete the automatic filling in the absence of personal operating conditions.

| Filling Nozzle | 1 Nozzle | 2 Nozzle | 4 Nozzle | 6 Nozzle | 8 Nozzle | 10 Nozzle | 12 Nozzle |

| Filling Speed | 20 bot/min | 25 bot/min | 30 bot/min | 40 bot/min | 50 bot/min | 60 bot/min | 70 bot/min |

| Filling Volume | 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml | ||||||

| Filling Accuracy | ±0.5-1% | ||||||

| Power Voltage | 220V/380V/410V/440V, 60Hz, 3 Phase | ||||||

| Air Consumption | 0.5-0.7Mpa | ||||||

| Remark |

1. The filling speed based on 500ml/bottle water.

2. More options can be customized according to your requirements.

|

||||||

Product Features:

- The equipment has strong compatibility, and can quickly adjust and replace bottles of different shapes and specificationswithout replacing parts, which can meet the production requirements of multiple varieties and specifications.

- PLC control ,touch bottle operatation ,simple and convenient operation.

- The use of internatioal famouse brand electrical components, performance and stability.

- User can adjust filling range, the materials is not enough in hopper, the computer will give the feeding pump signal to

addmaterial by level sensor. When the material is full, the pump will stop automatically.

- Machine body is made by 304 stainless steel, easy to clean, machine is full compliance with GMP requirements.

- Peristaltic pump or piston pump filling system, measuring precision, convenient manipulation.

Product Details:

1. Filling Nozzles: 1/2/4/6/8/10/12 Customizable no-drop filling nozzles. Different sizes to fit different bottles, easy to be assembled.All the material contact part is made of stainless steel 316L.

2. Various Filling Range: 10-150ml, 25-250ml, 50-500ml, 100-1000ml, 250-2500ml, 500-5000ml. With adjustable speed conveyor belt, and high strength stainless steel frame, firm and wear-used.

3. Servo Piston Motor: Servo motor control filling, higher filling accuracy and more stable performance.

4. PLC Control System: PLC touch screen control system, high class appearance, easier and faster for operation.

![]()

![]()

![]()

![]()

After-sales service:

We guarantee the quality of the main parts within 12 months. If the main parts go wrong without artificial factors within one year, we will freely provide them or maintain them for you. After one year, if you needto change parts, we will kindly provide you with the best price or maintain it in your site. Whenever you have technical question in using it, we will freely do our best to support you.