Liquid Soap 3000L High Shear Emulsifier Mixer Machine Steam Heating

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, TUV, SGS, GMP |

| Model Number: | PMC-3000L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 30 Working Days |

| Payment Terms: | T/T, D/A, L/C |

| Supply Ability: | 20 Sets Per Month |

|

Detail Information |

|||

| Available Capacity: | 30L To 6000L | Tank Structure: | 3 Layers Of Steel, 2 Jacket |

|---|---|---|---|

| Material: | SUS316L/SUS304/SUS304 | Heating Method: | Electric Heating / Steam Heating |

| Cooling: | Water Cooling | Mixing Method: | One Way Or Two Way Mixing With Teflon Scraper |

| Mixing Speed: | 0-65RPM | Homogenizer Speed: | 3000RPM |

| Highlight: | Liquid High Shear Emulsifier Mixer,Soap High Shear Emulsifier Mixer,Steam Liquid Soap Machine Mixer |

||

Product Description

3000L High Shear Shampoo Mixing Tank Liquid Soap Mixer Circulation Emulsifier

Brief Introduction:

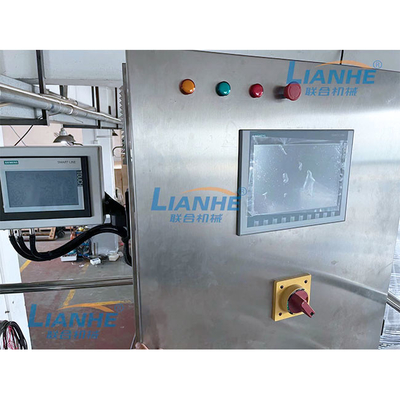

1) The stainless steel mixing tank has a mixer, bottom homogenizer, motor, electric control box, operating platform, stairs, etc.

2) The mixing speed of the scraper mixer adopts the frequency converter to adjust the speed, so that the product quality is high

Different processes according to customer requirements.

3) A variety of high-speed homogenizers, which can strongly mix solid and liquid raw materials and dissolve quickly

In the production process of liquid detergent, various insoluble substances such as AES, AESA and LSA are added to save energy consumption and shorten the production cycle. The high shear homogenizer adopts German technology, 0~3600rpm variable speed, and the shearing degree is about 0.2~5um.

4) The tank body is welded with three layers of stainless steel plates. The tank body and pipes are mirror polished or matte, fully complying with GMP requirements.

5) According to customer requirements. It is easy to unload, and the bottom is directly unloaded or pumped.

6) We can choose PLC automatic control system, or manual button control box, it depends on your needs.

![]()

![]()

Technical Parameter:

|

Model |

Capacity (L) |

Agitator |

Homiogenizer |

Heating system |

|||

|

power (kw) |

speed (rpm) |

power (kw) |

speed (rpm) |

Electric heating (kw) |

Steam heating (Mpa) |

||

|

PMC-50 |

50 |

0.75 |

0-65 |

3 |

3000 |

6 |

Steam heating energy conservation and environmental protection, selected according to need |

|

PMC-100 |

100 |

1.5 |

0-65 |

4 |

3000 |

9 |

|

|

PMC-150 |

150 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-200 |

200 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-300 |

300 |

1.5 |

0-65 |

5.5 |

3000 |

18 |

|

|

PMC-500 |

500 |

2.2 |

0-65 |

7.5 |

3000 |

27 |

|

|

PMC-1000 |

1000 |

4 |

0-65 |

11 |

3000 |

36 |

|

|

PMC-1500 |

1500 |

5.5 |

0-65 |

15 |

3000 |

45 |

|

|

PMC-2000 |

2000 |

7.5 |

0-65 |

15 |

3000 |

recommend steam heating |

|

|

PMC-3000 |

3000 |

11 |

0-65 |

15 |

3000 |

||

|

PMC-5000 |

5000 |

11 |

0-65 |

22 |

3000 |

||

|

The parameters for reference only, all the machines can be customized accordingly. |

|||||||

![]()

Application Product:

1. Cosmetics industry: skin cream, shaving cream, sunscreen, facial cleanser, nutritional honey, dye cream, ion iron, hydrogen peroxide, etc., essence, moisturizing cream, hand cream, etc.

2. Daily chemical industry: detergent, shampoo, shower gel, conditioner, laundry detergent, hand sanitizer, toilet cleaning, car glass water, detergent, tire wax, cleaning cream, etc.

3. Pharmaceutical industry: latex, emulsion, various ointments (ointments), antibiotics, injections, oral syrups, oral liquids, gels, etc.

4. Food industry: jam, chili sauce, food slurry, condiment, cheese, nutrient solution, baby food, chocolate, sugar, etc.

5. Chemical industry: latex, saponified products, paints, coatings, resins, adhesives, New materials, etc.

6. Comprehensive: production equipment for various liquid products such as resin coatings, paints, shoe polish, chemical fibers, etc., supports a variety of liquid technologies, the machine has beautiful appearance, low noise, and is easy to move. The machine can be customized according to requirements, can be heated at a constant temperature, and can be selected from various styles of stirring blades.

![]()

Option:

* With Platform or movable tank

* with Steam heating/ electric heating/ Single Layer

* Mixer type

* Bottom Homogenizing/ Dispersing

* Explosion-proof electric box/ PLC controller

* Half open hinged lid/ Seal lid

![]()

Customer's Reviews:

![]()

Exhibition & Project Cases:

![]()

C