SUS316 Cream High Shear Emulsifier Shampoo Conditioner Mixer 3000L With 2 Jacket

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, TUV, SGS, GMP |

| Model Number: | PMC-3000L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 30 Working Days |

| Payment Terms: | T/T, D/A, L/C |

| Supply Ability: | 20 Sets Per Month |

|

Detail Information |

|||

| Available Capacity: | 30L To 6000L | Tank Structure: | 3 Layers Of Steel, 2 Jacket |

|---|---|---|---|

| Material: | SUS316L/SUS304 | Heating Method: | Electric Heating / Steam Heating |

| Cooling: | Water Cooling | Mixing Method: | One Way Or Two Way Mixing With Teflon Scraper |

| Mixing Speed: | 0-65RPM | Homogenizer Speed: | 3000RPM |

| Highlight: | SUS304 High Shear Emulsifier Mixer,2 Jacket High Shear Emulsifier Mixer,3000L Cream Emulsifier Mixer |

||

Product Description

SUS316 Cream High Shear Emulsifier Shampoo Conditioner Mixer 3000L With 2 Jacket

Brief Introduction:

Our company's PMC series mixing tanks are widely used in the preparation of dairy, food, pharmaceutical, chemical (detergent, shampoo, shower gel, laundry detergent, bleach, glass cleaner, shampoo, etc.), beverages and other products. It integrates the functions of stirring and discharging (optional with working platform, stirring belt speed regulation, scraping wall stirring, belt dispersion or high shear homogeneous emulsification), and it is an ideal equipment for manufacturers to prepare liquids.

Before use, put the solid or liquid in the mixing tank, and heat the liquid while charging and stirring, and then put it in the storage tank. It can be used in food (dairy) products, pharmaceuticals, daily chemicals, beverages, oils, chemicals, pigments and other industries as intermediate buffering, liquid storage, stirring, mixing equipment heating, mixing and sterilization treatment.

![]()

Technical Parameter:

| Model | Capacity (L) | Agitator | Homiogenizer | Heating system | |||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | Electric heating (kw) | Steam heating (Mpa) | ||

| PMC-50 | 50 | 0.75 | 0-65 | 3 | 3000 | 6 | Steam heating energy conservation and environmental protection, selected according to need |

| PMC-100 | 100 | 1.5 | 0-65 | 4 | 3000 | 9 | |

| PMC-150 | 150 | 1.5 | 0-65 | 4 | 3000 | 12 | |

| PMC-200 | 200 | 1.5 | 0-65 | 4 | 3000 | 12 | |

| PMC-300 | 300 | 1.5 | 0-65 | 5.5 | 3000 | 18 | |

| PMC-500 | 500 | 2.2 | 0-65 | 7.5 | 3000 | 27 | |

| PMC-1000 | 1000 | 4 | 0-65 | 11 | 3000 | 36 | |

| PMC-1500 | 1500 | 5.5 | 0-65 | 15 | 3000 | 45 | |

| PMC-2000 | 2000 | 7.5 | 0-65 | 15 | 3000 | recommend steam heating | |

| PMC-3000 | 3000 | 11 | 0-65 | 15 | 3000 | ||

| PMC-5000 | 5000 | 11 | 0-65 | 22 | 3000 | ||

| The parameters for reference only, all the machines can be customized accordingly. | |||||||

![]()

Application Product:

1) Cosmetics industry:

Skin care cream, shaving cream, shampoo, toothpaste, cold cream, cold sun cream, facial cleanser, nutrient dense, detergent, shampoo, serum, moisturizing cream, hand cream, etc.

2) Daily chemical:

Laundry liquid, hand sanitizer, detergent, toilet cleaning, car glass water, etc.

3) Pharmaceutical industry:

Latex, cream, ointment (ointment), oral syrup, oral liquid, etc.

4) Food industry:

Sauce, cheese, nutrient solution, oil, baby food, chocolate, sugar, etc.

5) Chemical industry:

Latex, sauces, saponified products, paints, coatings, resins, adhesives, lubricants, etc.

![]()

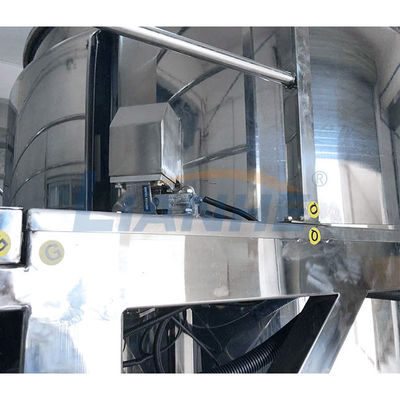

Hydraulic lifting system: It can be used to lift large barrels of raw materials.

![]()

Features:

- The all-around wall Teflon scraping mixing adopts the frequency inverter for speed adjustment, so it can be adjusted to make different products with different manufacturing requirements.

- The diversified high-speed homogenizer can powerfully mix solid, oil and liquid raw materials and can rapidly dissolve many indissoluble materials such as AES, AESA, LSA,etc.

- The pot body is welded by SUS316 three-layer stainless steel plate.the tank body and the pipes adopt 5 times mirror polishing, which fully conforms to GMP standard requirements.

- The motor for homogenizer and mixing paddle, we only use Siemens or ABB, with higher quality, better stability and longer service life.

- All main parts of the machine are adopted with international brands, such as Delta, Schneider, Siemens, Omron, etc.

Customer's Reviews:

![]()

Exhibition & Project Cases:

![]()

C