50L Vacuum Emulsifier Mixer Industrial Mixing Tank With Hydraylic Lifting System

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, SGS, TUV |

| Model Number: | VME-100 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, D/A, L/C |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Main Tank Structure: | 3 Layers, 2 Jackets | Material: | SUS316L/SUS304/SUS304 (in/mid/out) |

|---|---|---|---|

| Working Capacity: | 5L-6000L | Mixing Speed: | 0-65RPM |

| Mixing Method: | Two Way Mixing With Wall Scraper | Homogenizer: | 0-3600RPM |

| Tank Structure: | Main Tank + Water Tank + Oil Tank | Vacuum System: | -0.1MPa |

| Highlight: | 50L Vacuum Emulsifier Mixer,Hydraylic Lifting Vacuum Emulsifier Mixer,Vacuum Emulsifier Mixer 3600RPM |

||

Product Description

50L 100L Vacuum Emulsifier Mixer Industrial Mixing Tank with Hydraylic Lifting System

![]()

Application Product:

- Skin & Hair Care: Body lotion, facial cream, sunscree cream, serum, hair dye, hair conditioner, etc.

- Cosmetic: Liquid foundation, BB cream, mascara, lipstick, concealer, lip gloss, etc.

- Pharmaceutical: Ointment, erythromycin eye ointment, Compound Dexamethasone Acetate, etc.

- Food: Mayonnaise, ketchup, cheese, sauce, paste, coconut oil, etc.

![]()

Brief Introduction:

The vacuum emulsifier mixer mainly consists of water pot, oil pot, emulsifying pot (main tank), vacuum system, hydraulic lifting system (optional), button or PLC control system, operation platform, etc.

For different capacity requirements, we can customize the capacity from 5 litre to 6000 litre, and different homogenizer options for your choice.

The machine is widely used in Cosmetic, Daily Chemical, Food and Pharmaceutical area for manufacturing viscous and none-viscous liquid products, such as cream, paste, sanitizer gel, body lotion, hair dye, ointment, sauce, mayonnaise, etc.

Featured by easy operation, stable performance, good homogenizing performance, high productivity, easy cleaning, reasonable structure, space saving, etc.

This machine is used for cosmetic cream and lotions,The vacuum emulsifier is professionally designed according to the ointment manufacturing process of cosmetics and ointments etc. products through introducing advanced technology from abroad. The machine unit is composed of pre-treating boiler, vacuum emulsifying and blending boiler, vacuum pump,hydraulic system, dumping system, electric control system and work platform etc. The machine unit is featured by simple operation, stable performance, good homogenizing performance, high production efficiency, convenient cleaning, reasonable structure, small land area and high automatic degree etc.

Standard Configuration:

- Emulsifier, water phase tanks, oil phase tank

- Vacuum pumps and sync solenoid valves

- Emulsifier and material filter

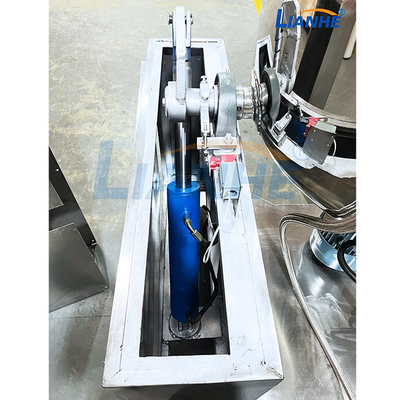

- Hydraulic lifting system and mixing system

- Stainless steel platform

- Inverter and electrical control box

Technical Parameter:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters are for reference only, all the machines can be customized according to your needs. | ||||||||

Working Method:

- Our company's emulsification equipment usually has one-way mixing, two-way mixing, internal and external circulation mixing 45degree inclined blade ensures material rolling and stirring effect.

- The control center can be divided into touch screen or button control, you can choose the console that suits you according to yourcustomization

- Vacuum defoaming makes the material reach the requirement of sterility. Use vacuum suction, especially powdery materials, vacuum suction can avoid dust. 2. The emulsification pot cover can adopt a lifting system, which is convenient to clean, and thecleaning effect is more obvious. The emulsification pot can be poured water. 3. The pot body is welded with imported three-layerstainless steel plate. The tank body and pipeline adopt mirror polishing, which is in full compliance with GMP requirements.

- According to your customized size and capacity, the motor power will also be different, so as to better adapt to differentmachines and create comfortable mechanical equipment.

Machine Details:

![]()

![]()

![]()

Customer's Reviews:

![]()

Exhibition & Project Cases:

![]()