5L High Speed Lab Cream Vacuum Emulsifier Homogenizer Lotion Vacuum Mixer

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 5 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 25 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 25 Sets per Month |

|

Detail Information |

|||

| Product Name: | Lab Cream Emulsifiers Small Lab Cream Lotion Mixer | Lab Capacity: | 5-50L |

|---|---|---|---|

| Heating Method: | Electric | Usage: | Cream Mixing Machine |

| Application Scope: | Chemical Cosmetic Food Pharmacy | Power(W): | Base On The Size |

| Highlight: | Lab Cream Vacuum Emulsifier Homogenizer,5L Vacuum Emulsifier Homogenizer |

||

Product Description

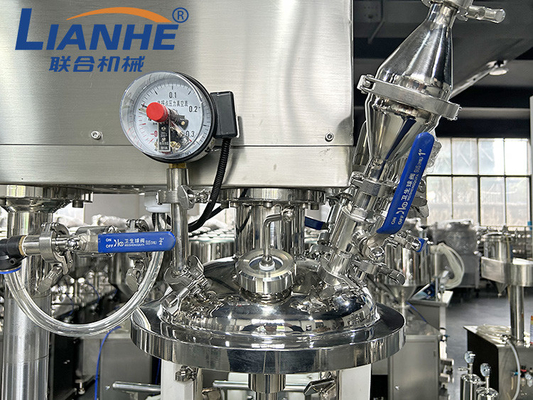

5L High Speed Lab Cream Vacuum Emulsifier Homogenizer Lotion Vacuum Mixer

Product Description:

Vacuum emulsifying machines are widely used in various industries because they provide a cost-effective and low-material-loss method of handling materials that need mixing and emulsification. The industrial mixing of liquids, solids, and powders may all be done with the vacuum emulsifier. A vacuum emulsification machine is a full vacuum mixer system used in the cosmetics, pharmaceuticals, food, and chemicals industries to produce viscous cream, lotion, ointment, and suspensions.

Product Composition:

The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, lifting system (optional), electric control system (PLC is optional), operation platform, etc.

Product Structure:

The emulsifying machine is primarily comprised of an emulsification tank (with a liftable tank lid or flip tank), an oil phase tank, a water phase tank, a vacuum system, a heating and temperature control system, and an electrical control system. The vacuum emulsifier has more adaptability and diversity in material handling due to the replaceable operating unit, adjustable speed and frequency conversion, and temperature control system.

Product parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Now, look at a few industries that use vacuum emulsifying mixer:

1. Cosmetic Industry

2. Pharmaceutical Industry

3. Food Industry

4. Chemical Industry

FAQ:

Q1:Do you supply OEM/ODM service?

Yes, according to customer product requirements to design product shape and size .3D drawing provided.

Q2:What about the production time?

15-30days, except in stock.

Q3:How to install and operate machine?

I.All machines with English Language Manual;

II.Each working unit installation and operation video;

III.3D drawing for product shape and size;

IV.24h e-service online and on site operation live video for teaching;

V.Each machine working unit drawing provided.

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte