Customization Ointment Baby Oil Face Cream Vacuum Mixing Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 50 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 25working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 25 Sets per Month |

|

Detail Information |

|||

| Material: | SUS 316L & 304 | Core Components: | Motor, Pump, PLC, Other, Engine |

|---|---|---|---|

| Function: | Mixing , Heating , Homogenizing , Vacuum | Homogenizer: | Bottom Or Top |

| Homogenizing Speed: | 0-3600 Rpm | Mixing Speed: | 0~65 R/min |

| Mixing Way: | Double Direction Mixing | Control: | Touch Screen Or Button Control |

| Highlight: | Ointment Face Cream Vacuum Mixing Machine,3600rpm Vacuum Mixing Machine |

||

Product Description

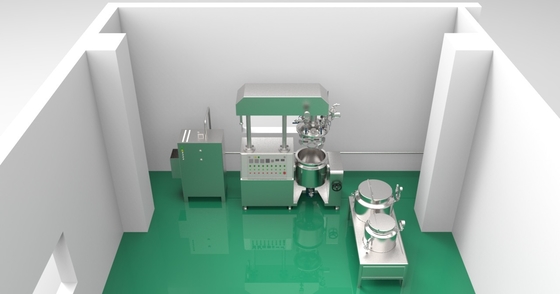

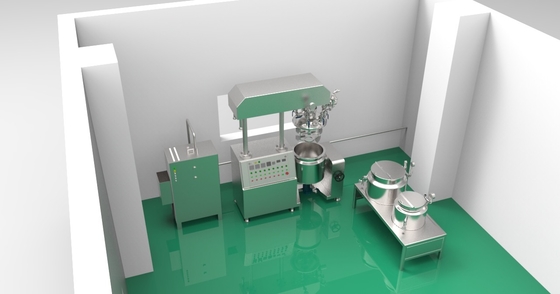

Factory Customization Ointment Baby Oil Face Cream Vacuum Mixing Machine

Application Product:

- Skin & Hair Care: Body lotion, facial cream, sunscree cream, serum, hair dye, hair conditioner, etc.

- Cosmetic: Liquid foundation, BB cream, mascara, lipstick, concealer, lip gloss, etc.

- Pharmaceutical: Ointment, erythromycin eye ointment, Compound Dexamethasone Acetate, etc.

- Food: Mayonnaise, ketchup, cheese, sauce, paste, coconut oil, etc.

![]()

Brief Introduction:

The vacuum emulsifier mixer mainly consists of water pot, oil pot, emulsifying pot (main tank), vacuum system, hydraulic lifting system (optional), button or PLC control system, operation platform, etc.

For different capacity requirements, we can customize the capacity from 5 litre to 6000 litre, and different homogenizer options for your choice.

The machine is widely used in Cosmetic, Daily Chemical, Food and Pharmaceutical area for manufacturing viscous and none-viscous liquid products, such as cream, paste, sanitizer gel, body lotion, hair dye, ointment, sauce, mayonnaise, etc.

Featured by easy operation, stable performance, good homogenizing performance, high productivity, easy cleaning, reasonable structure, space saving, etc.

Standard Configuration:

- Emulsifier, water phase tanks, oil phase tank

- Vacuum pumps and sync solenoid valves

- Emulsifier and material filter

- Hydraulic lifting system and mixing system

- Stainless steel platform

- Inverter and electrical control box

Technical Parameter:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters are for reference only, all the machines can be customized according to your needs. | ||||||||

Working Method:

The materials in the water-phase tank and oil-phase tank are heated up and stirred. After they are thoroughly mixed, they will be transferred to the emulsifying tank by the vacuum pump. The material will be stirred by the upper part of the central paddle, combined with the PTFE scraper sweeping the wall, the material will be stirred thoroughly and meanwhile be pushed down to the emulsifier at the low part of the central axle. With a very high-speed emulsifying effect, the material will be seriously cut, sheared, and cracked into 200nm - 2um particles. The bubbles that appear during the process will be sucked out promptly in the vacuum status in the tank.

Machine Details:

![]()

![]()

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte

Why choose us?

Lianhe Machinery is a scientific enterprise specializing in research, development, production, and management of cosmetic, food, and pharmaceutical machinery, filling machinery, and packing machinery. We have complete machining equipment, perfect technological flow, powerful technical force, excellent product development, and design ability as well as rich production experience.

Customer's Reviews:

![]()

D