300L Vacuum Emulsifier Mixer Antigen Reagent Solution Making Machine Heating tank

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 20 Sets per Month |

|

Detail Information |

|||

| Material: | SUS316L & SUS304 | Capacity: | 300L (can Be Customized From 50L-6000L) |

|---|---|---|---|

| Voltage: | 220V / 380V Customized | Motor Brand: | SIEMENS Or ABB Only |

| Mixing Speed: | 0-65 Rpm | Application: | Cosmetic, Daily Chemical, Food, Pharmaceutical |

| Highlight: | SUS304 Vacuum Emulsifier Mixer,300L Vacuum Emulsifier Mixer |

||

Product Description

Antigen Reagent Solution Making Machine , Mixing And Heating Tank

Product Description:

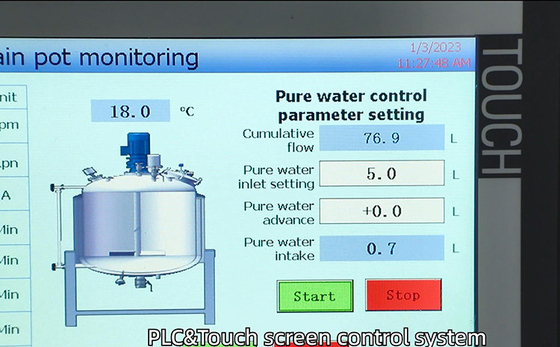

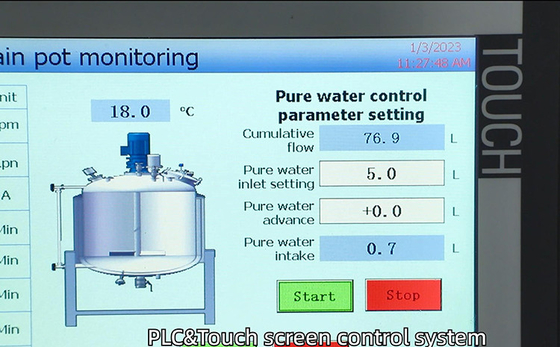

This 300L Fixed Type Mixing and Heating Mahcine equipped with Flowmeter, customers use it to produce antigen reagents

It has a large processing capacity in continuous work. It is suitable for continuous processing of single-variety products. The mixing system of the machine is designed to produce creams and liquids of different viscosities. The speed can also be adjusted according to customer preferences. The vacuum system will ensure successful operation by preventing the formation of bubbles in the material.

![]()

Product Parameters :

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Main Features :

We can customize mixing machine with different function according to different product. Our machine has such features as simple operation, stable performance, good homogenization, high production efficiency, convenient cleaning, reasonable structure, small floor space, and high automatization etc.

- The vacuum emulsifiers produced by our company include many varieties.The homogenizing systems include upper homogenization,lower homogenization,internal and external circulating homogenization.The mixing systems include single-way mixing,double-way mixing and helical mixing.The lifting systems include single-cylinder lifting and double-cylinder lifting.Various high quality products can be customized according to customers' requirements.

- The triple mixing adopts the imported frequency converter for speed adjustment,which can meet different technological demands.

- The homogenizing structure made through German technology adopts the imported double-end mechanical seal effect.The maximum emulsifying rotation speed can reach 4,200rpm and the highest shearing fineness can reach 0.2-5um.

- The vacuum defoaming can make the materials meet the requirement of being aseptic.The vacuum material sucking is adopted,and especially for the powder materials,vacuum sucking can avoid dust.

- The pot body is welded by imported three-layer stainless steel plate.The tank body and the pipes adopt mirror polishing,which fully conforms to GMP requirements.

- According to technological requirements,the tank body can heat and cool the materials.The heating modes mainly include steam heating and electric heating.

- To ensure the control of the whole machine is more stable,the electric appliances adopt imported configurations,so as to fully meet the international standards.

The vacuum emulsifying mixer are mainly used to make high viscosity emulsions, especially creams, ointments and lotions. The functions of heating, cooling, dissolving, emulsification and vacuum defoaming can be completed at one time with an emulsifier; the raw materials can be fully pulverized, mixed, emulsified and homogenized to increase the gloss and stability of the product.

Our Service:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, maintain.