LIANHE Ultrasonic Tube Filling Machine Semi Automatic PLC Control

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-FS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Material: | Stainless Steel 304/316 | Control: | PLC + Servo Motor Control |

|---|---|---|---|

| Function: | Filling And Sealing | Packaging Material: | Plastic And Laminated Tube |

| Tube Length: | 50-210 Mm | Filling Range: | 5-250ml |

| Highlight: | LIANHE Tube Filling Machine,Ultrasonic Tube Filling Machine,PLC Ultrasonic Tube Filling Sealing Machine |

||

Product Description

Semi Automatic Ultrasonic Tube Filling Machine Cosmetic Sealing Machine

Product Description:

Tube filling and sealing machine is suitable for filling all kinds of pasty and viscous fluid and the materials alike, into plastic and composite metal tube and then internally heating tubes, sealing and printing lot number. It is used in the industries of pharmaceutics, foodstuffs, cosmetic and daily chemicals. With Taiwan's EVIEW touch screen and Siemens PLC control system employed, convenience, visualized and realizable nontouch operation of the machine is effected compact design and auto tube feed.

Product Parameters:

|

Filling volume |

5-250ml(tube) |

|

Filling accuracy |

≤±1% |

|

Capacity |

40 tubes/min(normal type); 60-70 tubes/min(high speed type) |

|

Tube diameter |

OD10-50mm |

|

Tube length |

210mm(Max. length) |

|

Hopper volume |

40L |

|

Power |

220V/380V, can be customized |

|

Air pressure |

1.1KW |

|

Equipped motor |

0.5-0.7Mpa |

|

Air feeding |

0.37KW |

|

Convulsions |

0.37KW |

|

Hot air |

3KW |

|

Dimension |

3KW |

|

Weight |

1800kg (approx) |

Product Application:

The tube filling and sealing machine is suitable for automatic color code aligning, filling, sealing, date printing and end cutting of various plastic tubes and aluminum composite tubes. It is widely applied in daily chemical industry, medicine, food, etc.

Product Features:

1. The reasonable design, simple operation, suitable for many sets of mould, easy to change.

2. The function is all ready, versatility, suitable for all kinds of plastic pipe aluminum composite pipe.

3. of the PLC control system, color code detection more accurate, try long life.

4. Adopting drip tight protection wire filling system, liquid paste can apply.

5. Heating method for copper inside outside heating and heating, to ensure the sealing strong and beautiful. Temperature and blowing gas adjustment convenient and quick, convenient mould replacement, low cost.

6. Date and batch number printing function, can double code.

Product Details:

1. 8-station turntable: Tube holder is designed for positioning the tubes, enabling them to be filled and sealed well. The molds can be customized according to tube's size.

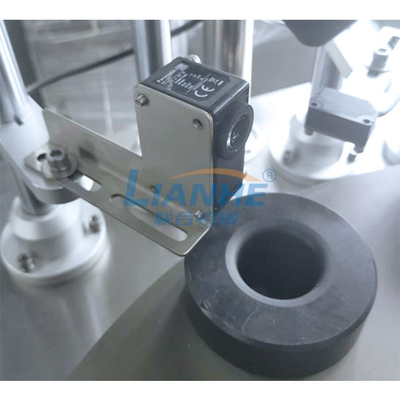

2. Cursor Positioning: Automatic detection and positioning. No tube no filling and no sealing.

3. Filling Head: Filling accuracy≤ ±1% and Anti-drip filling nozzle.

4. Sealing: Heating or ultrasonic sealing. Simple operation: fast welding speed; high welding strength; high work efficiency.

5. Cutter: Automatically cut off the remaining material to make the seal more smooth.

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte