Cosmetic Cream Vacuum Emulsifier Mixer 300L-500L Agitator 65 Rpm

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 300 - 500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 5L - 5000L | Material: | SUS304, SUS316L |

|---|---|---|---|

| Function: | Emulsion, Homogenizing, Mixing, Heating, Vacuum | Homogenizer Design: | Top, Bottom Or Circulation Homogenizer |

| Motor Brand: | SIEMENS Or ABB Only | Control System: | PLC Or Button |

| Dimension(L*W*H): | Can Be Customized | Key Selling Points: | Low Maintenance Cost |

| Highlight: | 300L Vacuum Emulsifier Mixer,Cream Vacuum Emulsifier Mixer,500L Cosmetic Cream Mixer |

||

Product Description

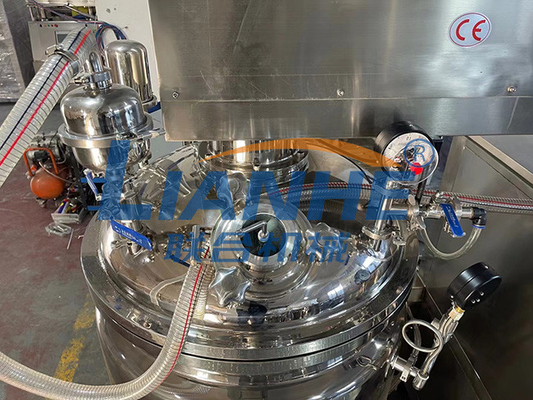

300L - 500L Cosmetic Cream Ointment Gel Hydraulic Lifting Vacuum Emulsifying Mixer

Product Description:

Vacuum emulsifier emulsification homogenization is mainly used to make high-viscosity emulsions, especially creams, ointments and lotions. Use the emulsifier to complete the functions of heating, cooling, dissolving, emulsification and vacuum defoaming at one time; the raw materials can be fully crushed, mixed, emulsified, and homogenized to increase the gloss and stability of the product.

Homogenizer Working Principle:

The material is emulsified in the shear crack through the strong shear, impact and turbulence between the high-speed rotating rotor and stator, and quickly crushes into 200 nm-2um. Material granulation, emulsification, mixing, blending and dispersion can be completed in a short time.

Product Structure:

![]()

Product parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Product Advantage:

The vacuum emulsifying mixer machine produces cream and lotion with a fine, smooth, glossy form and a highly stable essential material. During the production process, operators must have a wide range of skills and abilities to produce the best cream. The classic way of making cream is to heat the oil and water at a temperature, mixing, packing materials, emulsifying, and cooling. On the other hand, the vacuum emulsifying mixer machine's cream is bubble-free, supple, smooth, and has a long life shelf.

Our Service:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, maintain.