ISO 300L Toothpaste Manufacturing Equipment , SUS316L Cosmetic Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 300 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 1000L (can Be Customized) | Hydraulic Lifting And Tilting System: | Optional |

|---|---|---|---|

| Material: | SUS304, SUS316L | Heating Method: | Steam Or Electric (Optional) |

| Key Selling Points: | Long Service Life | Motor Brand: | SIEMENS Or ABB Only |

| Highlight: | ISO Toothpaste Manufacturing Equipment,300L Toothpaste Manufacturing Equipment,SUS316L Cosmetic Making Machine |

||

Product Description

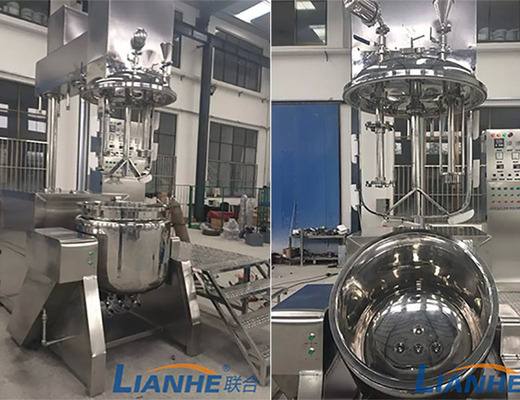

300L Toothpaste Making Machine Vacuum Homogenizer Emulsifying Mixer

Product Description:

The vacuum toothpaste making machine is the key equipment for the production of toothpaste and paste, and its characteristics are:

(1) The paste preparation is carried out in a closed container under a vacuum state.

(2) Equipped with paddle stirring and scraper, so that the material does not have accumulation and dead angle.

(3) Equipped with a high-speed homogenizer or a colloid mill to make the material uniform and fine.

(4) One-step process can be adopted to complete all paste-making operations in the paste-making machine, which can significantly reduce material loss.

(5) Supporting raw material conveying system, automatic metering and control system, through computer operation, realize paste-making automation.

Product Parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Main Features:

The structural features of the paste making machine are:

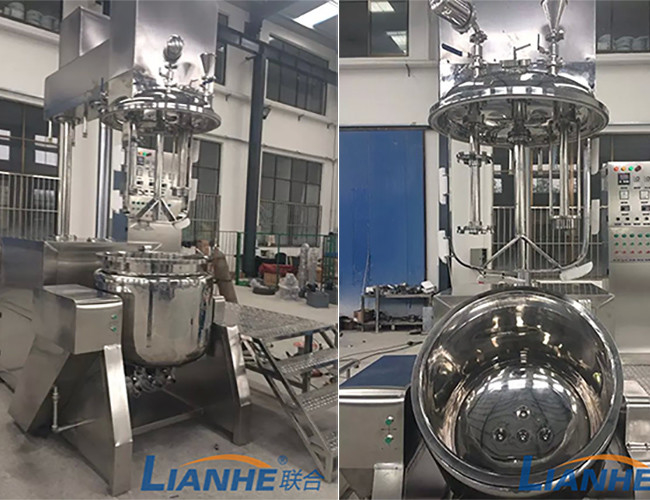

(1) The cylinder is made of three-layer, stainless steel material inside and outside, the positive pressure resistance is 0.2MPa, the negative pressure resistance is -0.1MPa, the jacket is used for heating or cooling, and the positive pressure resistance is 0.3Mpa.

(2) The scraper stirring is that the large wall-mounted scraper and the central scraper rotate in positive and negative directions. During stirring, the material can be scraped off the wall of the cylinder, the temperature is transmitted evenly and fully, and the effect of turning up and down is formed.

(3) High-speed homogenizer, the speed is 3600RPM, and the gap between the inner and outer rotors is 1-2mm. After the powder is inhaled from the bottom, it is ejected to the top through the homogenizer, so as to achieve the effect of making the paste fine. (4) The vacuum pump adopts a water-sealed two-stage vacuum pump, and is equipped with a buffer tank between it and the paste making pot to isolate the materials that are accidentally brought out.

(6) The jacket cooling adopts circulating water, the water pressure is controlled below 0.3Mpa, and the temperature is set by the control system.

(7) The discharge port is located at the bottom of the paste making pot, and the material is discharged by a colloid pump with a flow rate greater than 100L/min.

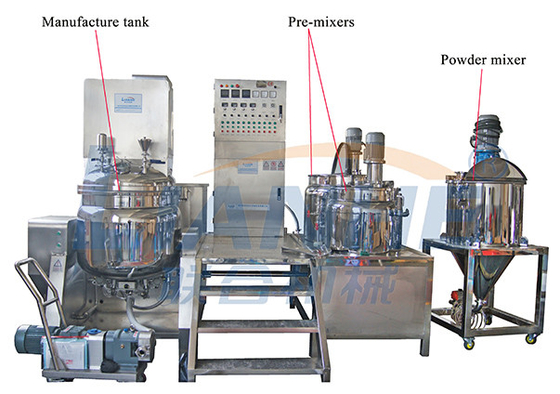

Toothpaste Production Line:

![]()

Our Service:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, maintain.