65 Rpm 1000L Lotion Mixer Machine Cosmetic , Fixed Type Ointment Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 1000 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 1000L (can Be Customized) | Mixing Speed: | 0-65 Rpm |

|---|---|---|---|

| Homogenizing Speed: | 0-3600 Rpm | Motor Brand: | SIEMENS Or ABB Only |

| Material Contact Parts: | SUS316L , SUS304 | Dimension(L*W*H): | Can Be Customized |

| Highlight: | 65 Rpm Lotion Mixer Machine Cosmetic,1000L Lotion Mixer Machine Cosmetic,Fixed Ointment Making Machine |

||

Product Description

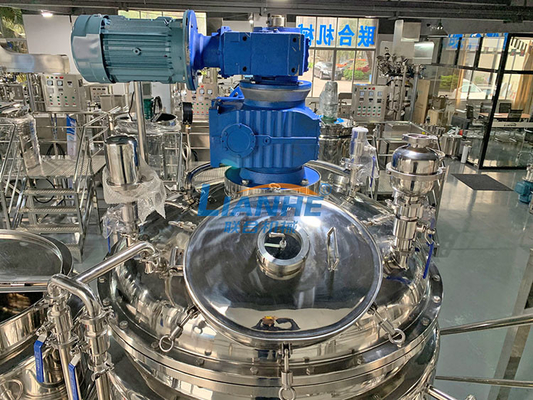

1000L Fixed Type Vacuum Emulsifying Mixer Machine With Two-Way Stirring Paddle

Product Description:

This 1000L Fixed Type vacuum emulsifying mixer equipped with a 500L oil tank.

It has a large processing capacity in continuous work. It is suitable for continuous processing of single-variety products. The mixing system of the machine is designed to produce creams and liquids of different viscosities. The speed can also be adjusted according to customer preferences. The vacuum system will ensure successful operation by preventing the formation of bubbles in the material.

![]()

Product Parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

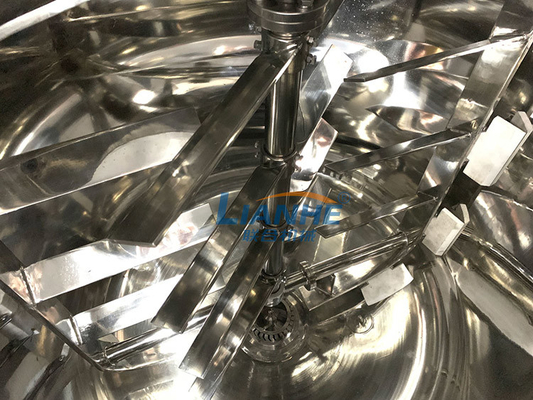

Homogenizer Working Principle:

The material is emulsified in the shear crack through the strong shear, impact and turbulence between the high-speed rotating rotor and stator, and quickly crushes into 200 nm-2um. Material granulation, emulsification, mixing, blending and dispersion can be completed in a short time.

Main Features:

- Fixed Vacuum Mixing Machine Capacity: 50L-5000L and other general specifications and non-standard design and production.

- The Emulsifying Tank lid adopts a Vacuum system, easy to clean, the emulsifying tank can adopt Positive pressure discharge.

- The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking adopted can avoid dust.

- PTFE scraping board cater to the body of blending groove and scrape out viscosity material on the boiler wall.

- Homogenizer is installed on the Fixed Vacuum Making Machine bottom to increase motor power more thoroughly and strongly. During a few productions, it can exert the homogenizing effect fully.

- SIEMENS frequency converter for speed adjustment of 0-3000 rpm, which can meet the production of different technology requirements.

- Burgmann mechanical sealing for Vacuum Mixing Making Machine, good sealing effect, and long working life. Material contact parts all use SUS316L stainless steel.

The vacuum emulsifying mixer are mainly used to make high viscosity emulsions, especially creams, ointments and lotions. The functions of heating, cooling, dissolving, emulsification and vacuum defoaming can be completed at one time with an emulsifier; the raw materials can be fully pulverized, mixed, emulsified and homogenized to increase the gloss and stability of the product.

Our Service:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, maintain.