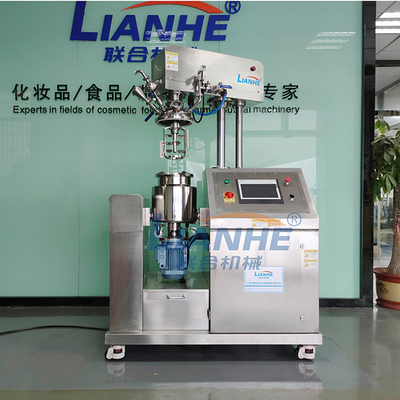

5-25L Body Lotion Vacuum Emulsifying Mixer Stainless Steel Material

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME 5-25 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 5L - 5000L | Mixer Type: | Homogenizer |

|---|---|---|---|

| Stirring Speed: | 0-65 Rpm | Homogenizing Speed: | 0-3600 Rpm |

| Heating Method: | Steam Or Electric (Optional) | Heating Temperature: | 0-100 ℃ |

| Highlight: | 5L Vacuum Emulsifier Mixer,25L Vacuum Emulsifier Mixer,Stainless Steel Body Lotion Making Machine |

||

Product Description

Stainless Steel 5-25L Vacuum Emulsifying Mixer Face Cleanser Body Lotion Making Machine

Product Description:

The vacuum emulsifying mixer is an industrial machine used for dispersing, viscous emulsifying, and product suspensions. The mixer operates on a fundamental principle that prevents dead or harsh corners from forming and purifies the products or materials. The equipment is used to refine and disperse a variety of products, including creams, ointments, lotions, and other liquid products on the market.

Product Composition:

The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, lifting system (optional), electric control system (PLC is optional), operation platform, etc.

Product Structure:

The pot cover is of automatic rising type. The material is directly drawn into the emulsifying boiler from oil boiler and water boiler. The discharge is based on the turning of the emulsifying boiler. And the heating system is electric heating and steam heating by the heating pipe, so the temperature is controlled automatically. Put the cool water into the intercalated bed so as to cool the material, which is simple and convenient (there is a warm layer outside the intercalated bed). The homogenizer and the stirring blades can work together or separately. The material sliming, emulsification, mixing, dispersing, etc. can be finished in a short time. Some parts of the machine are made of high-quality stainless steel (316L material will be adopted for medical use; the interior surface adopts mirror polish, vacuum agitating device is hygienically made according to the normal hygiene standard of GMP and is the most idea production equipment).

Product parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Now, look at a few industries that use vacuum emulsifying mixer:

1. Cosmetic Industry

2. Pharmaceutical Industry

3. Food Industry

4. Chemical Industry

FAQ:

Q1:Do you supply OEM/ODM service?

Yes, according to customer product requirements to design product shape and size .3D drawing provided.

Q2:What about the production time?

15-30days, except in stock.

Q3:How to install and operate machine?

I.All machines with English Language Manual;

II.Each working unit installation and operation video;

III.3D drawing for product shape and size;

IV.24h e-service online and on site operation live video for teaching;

V.Each machine working unit drawing provided.