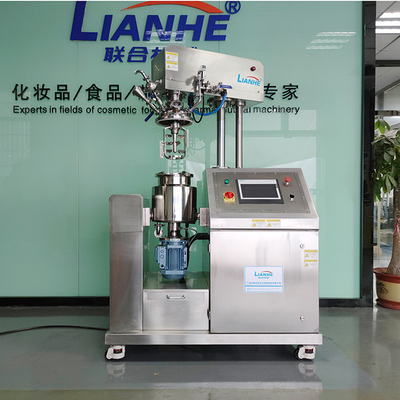

LIANHE PLC Lotion Manufacturing Equipment , 0.2 Mpa Face Cream Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME5 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 5L - 5000L | Material: | SUS316L & 304 |

|---|---|---|---|

| Mixer Type: | Homogenizer | Stirring Speed: | 0-65 Rpm |

| Homogenizing Speed: | 0-3600 Rpm | Heating Method: | Steam Or Electric (Optional) |

| Function: | Emulsion, Homogenizing, Mixing, Heating, Vacuum | Control System: | PLC Or Button |

| Highlight: | LIANHE Lotion Manufacturing Equipment,PLC Lotion Manufacturing Equipment,0.2 Mpa Face Cream Making Machine |

||

Product Description

Vacuum Emulsifying Mixer Body Lotion Emulsifier High Viscosity Cream Making Machine

Product Description:

The vacuum emulsifying mixer, also known as the vacuum homogenizing mixer, is a machine used to make cream and ointment, which will be used in different industries, including medical, pharmaceutical, cosmetics, chemicals, food, and beverages.

The vacuum emulsifying mixer is an industrial machine used for dispersing, viscous emulsifying, and product suspensions. The mixer operates on a fundamental principle that prevents dead or harsh corners from forming and purifies the products or materials. The equipment is used to refine and disperse a variety of products, including creams, ointments, lotions, and other liquid products on the market.

Product Composition:

The vacuum emulsifying mixer is mainly composed of water pot, oil pot, emulsifying pot, vacuum system, lifting system (optional), electric control system (PLC is optional), operation platform, etc.

Product Structure:

The vacuum emulsifying mixer consists of vacuum-resistant vessel with jacket for heating and cooling. Equipped with high speed homogenizer, scraping agitator, vacuum pump, and hydraulic pump for lifting, heating & cooling system.A vacuum emulsifying mixer comprises many parts, including electrical control system, a vacuum device, a heating, and cooling system, a temperature control system, and pots for oil, emulsifying, and water. The control panel is where all the mixer's operations carry out . The controls include the lighting power system, the main pot's constant functioning, control of the main pot's stirring operation, access to the vacuum system's operation, and the water and oil pot's mixing and heating process.

Product parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

Now, look at a few industries that use vacuum emulsifying mixer:

1. Cosmetic Industry

Machinery in a cosmetics manufacturing line is often made up of a number of different cosmetic types of equipment. The vacuum emulsifying mixers play an important role in machines and production plants as it is used to mix a wide range of beauty products such as:

• face cleansers

• shampoo

• body creams

• lotions

• hair gel

• lip balms

• shaving gel

• sunscreen

• lip gloss

2. Pharmaceutical Industry

Vacuum emulsifying mixers have also been shown to be beneficial in the production process of the pharmaceutical industry, such as on the production of:

• ointments

• oral syrups

• latex

• emulsions

The emulsification tank is equipped with a vacuum system that is completely sealed. Using the vacuum setting, the material can now be homogenized, emulsified, heated, and dispersed with little material contact with the surrounding environment. In this case, the required standard for cleanliness and sterility are attainable.

3. Food Industry

Sauces such as mayonnaise and salad dressings are a kind of flavoring sauce that is semi-solid in consistency. The acidic ingredients and high-fat emulsion are made using eggs, sugar, vegetable oil, salt, vinegar, spices, and emulsifying thickening agents, among other elements.

Therefore, the vacuum emulsifying mixer is one of the most often used pieces of manufacturing equipment in creating mayonnaise and other food products. The vacuum mixer may be used to mix a variety of dense materials such as:

• Mayonnaise

• dressings

• jam

• butter

• margarine

• cheese

4. Chemical Industry

The vacuum emulsifying mixer is also prevalent in chemical industry manufacturing. The equipment is useful for emulsifying synthetic fibers and polyesters and in the production of latex, saponification products, sauce, detergents, coatings, etc.

Other industrial sectors that have recognized the value of this equipment is:

• Nanometer materials

• Petrochemical industry

• Printing and dyeing auxiliaries

• Pulp and paper

• Pesticide fertilizer

• Plastic and rubber

• Electric and electronics

FAQ:

Q1:Do you supply OEM/ODM service?

Yes, according to customer product requirements to design product shape and size .3D drawing provided.

Q2:What about the production time?

15-30days

Q3:How to install and operate machine?

I.All machines with English Language Manual;

II.Each working unit installation and operation video;

III.3D drawing for product shape and size;

IV.24h e-service online and on site operation live video for teaching;

V.Each machine working unit drawing provided.