Leakproof Automatic Tube Packing Machine , Anticorrosive Tube Filling Equipment

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-FS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Material: | SUS304/316L | Filling Range: | 5-150m; 25-250ml; 30-500ml, Etc, Customized |

|---|---|---|---|

| Tube Length: | 50-210 Mm | Batch Printing: | Available |

| Key Selling Points: | High-Accuracy | Function: | Automatic Positioning, Filling, Heating, Sealing |

| High Light: | Leakproof Tube Packing Machine,Automatic Tube Packing Machine,Anticorrosive Tube Filling Equipment |

||

Product Description

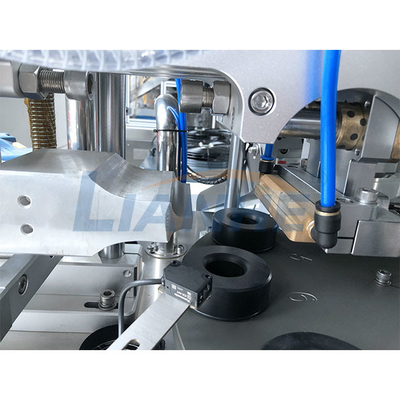

Fully Automatic Cream Plastic Tube Filling And Sealing Machine

Product Description:

This Automatic Cream Tooth Paste Aluminum Plastic Tube Filling Sealing Machine is high technical equipment which successfully developed and designed by introducing into advanced overseas technology and integrating GMP requirement, with features of fair structure, full function, easy operation, accurate filling, stable running, as well as low noise.

It adopt with PLC controller, automatically operating from liquid or high velocity material filling till batch number printing (include manufacture date), it's an ideal equipment for ALU tube, plastic tube and multiple tube filling and sealing in cosmetic, pharmacy, foodstuff, adhesives etc industries, comply with the standard of GMP.

Product Parameters:

|

Filling volume |

5-30ml; 6-60ml; 10-120ml; 30-200ml, 50-500ml, etc, customized |

|

Filling accuracy |

≤± 0.5-1% |

|

Capacity |

30-40 tubes per minute / 60-70tubes per minute |

|

Tube diameter |

OD 10-50mm |

|

Tube length |

210mm(Max. length) |

|

Hopper volume |

40L |

|

Power |

220V/380V, can be customized |

|

Air pressure |

1.1KW |

|

Equipped motor |

0.5-0.7Mpa |

|

Convulsions |

0.37KW |

|

Hot air |

3KW |

Product Application:

The tube filling and sealing machine is suitable for automatic color code aligning, filling, sealing, date printing and end cutting of various plastic tubes and aluminum composite tubes. It is widely applied in daily chemical industry, medicine, food, etc.

Product Advantages:

Auto Tube Orientation

Using high sensitivity Japan-Imported Panasonic infrared positioning system, plastic tube will be turning to right side according to the mark on the tube

Auto Inner Heating Sealing & Coding Function

Using Japan ultrasonic technology, sealing the plastic tube and coding on it.

Auto Cutting Function

It's with the function of automatically cutting after sealing and coding, in which guarantee the tube tail more beauty.

Inported AirTAC Solenoid Valve

Adopting famous brand AirTac air system, greatly make the machine pressure working precisely.

Product Features:

1.High grade operation screen with display PLC and buttons, easy operation and more humanization.

2.Automatically executing tube supply, photoelectron register, inert gas filling(optional), material filling and sealing, batch number printing, final products output.

3. High precision photoelectron register reduced the chromatic aberration scope.

4. Adjustment parts external in position, position digital display, convenient and accurate adjust (suitable for variety products producing).

5.Mechanical, photoelectron, electric, pneumatic integrative controlling, reaches no tube no filling function; Waiting if tube error position or pressure too low, automatic stop machine if open the protective door.

Product Details:

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte