Electric Leakproof Bottle Filling And Capping Machine Anticorrosive

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AC |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Applicable Cap: | Pump Head, Flip-top Head, Trigger Cap, Other Design | Production Capacity: | 30-50 Caps/Min |

|---|---|---|---|

| Control: | SIEMENS PLC Touch Screen | Machine Type: | Four-wheel Clamping |

| Driven Type: | Electric And Pneumatic | Applicable Cap Size: | 20-110mm (customized Available) |

| Highlight: | Electric Bottle Filling And Capping Machine,Leakproof Bottle Filling And Capping Machine,Anticorrosive Bottle Filling Capping Machine |

||

Product Description

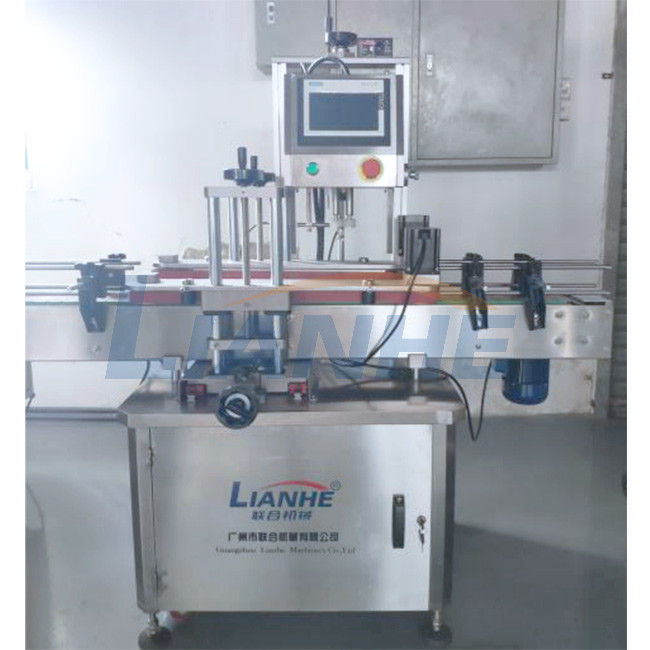

Automatic Screw Bottle Capping Machine Glass Plastic Cap Sealing

Product description:

Automatic screw cap machine with automatic caps feeding is the latest improvement of a new type of capping machine. Aircraft elegant appearance, smart,capping speed, high pass rate, applied to food, pharmaceutical, cosmetic, pesticides, cosmetics and other industries of different-shaped screw-cap bottle.

Four speed motors are used for cover, bottle clip, transmit, capping, machine high degree of automation, stability, easy to adjust, or replace the bottle cap when not spare parts, just make adjustments to complete.

![]()

Product application:

Suitable for bottles or jars, pump head, flip-top head, jars cap, trigger cap, essential oil dropper cap, etc. This machine is used for automatic capping for plastic bottles and glass bottles in cosmetic, food, beverage, chemical industry and medicine industry. It can be applied to a variety of bottle types with high production efficiency.

![]()

Product parameters:

| Technical Parameters | |

| Capping speed | 30-50 bottles per minute |

| Applicable cap | Flip-top type, pump-head type, trigger type, dropper type, and all other screw type cap |

| Capping form | 4 wheels clamp screw the cap |

| Material | Stainless steel 304 |

| Capping motor | 220W motor |

| Air Pressure | 0.6-0.8 Mpa |

| Cap feeding | Manually or automatically selectable |

| Voltage |

Single phase voltage, customized according to your request |

Product advantages:

- PLC Control System: Imported brands for PLC touch screen control system, high class appearance, easier and faster for operation.

- Anti-scratch Capping Wheel: 4 clamp capping wheel, silica gel material prevents scratches on the caps while working.

- Automatic Cap Feeding System (optional): Can equip with automatic cap feeding system, save manpower. Customize according to different cap design.

- Capping Motor: Motor controls capping wheel, ensure the stable performance and high working accuracy.

- Easy Adjustment System: With screw handles and clamping conveyor adjustment, easily to adjust the machine when change different bottles or different caps.One set machine can fit different shapes of bottles and caps.

- Wide Application: Machine with easy adjustment design for wide application, one set machine can serve various shapes of bottles and caps, such as jars, bottles; and flip-top caps, trigger caps, pump head caps, etc.

Product Features:

This machine is mainly applied to plastic or glass bottles, no matter round, square of other shapes. It can realize the goal of sorting caps, sending caps, screwing caps automatically.

1.This machine is equipped with a SIEMENS PLC touch screen device, fully automatic screw cap, suitable for all kinds of bottles, no liquid outflow.

2.The machine will accurately position each bottle.

3. Easy to operate, stable performance, widely used are features of this machine. It is widely used in pharmaceutical, chemical, food, beverage, light industry and other industries.

Product details:

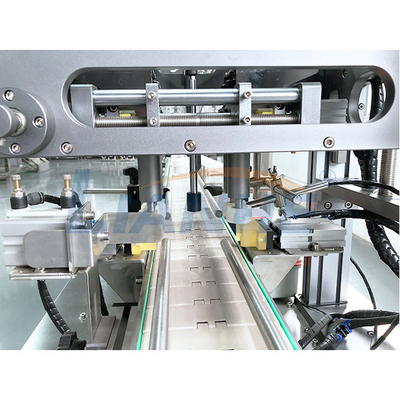

1. 4 wheels screwing capping head, its capping height and capping width is adjustable to suit your different caps diameter.

![]()

2. SIEMENS PLC touch screen control, high class appearance, stable performance.

![]()

3. Automatic cap feeding system can be added if you need.

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte

E