Single - Layer Stainless Steel Mixer Liquid Soap Lotion Blending Tank

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-PMC 500 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20-30 working days |

| Payment Terms: | T/T, L/C |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Material: | SUS304/SUS316(Material Contact Part) | Power Supply: | 220V/380V/3phase (Customized) |

|---|---|---|---|

| Mixing Speed: | 0-65 Rpm | Mixing Motor: | SIEMENS/ABB |

| Dimension(L*W*H): | Can Be Customized | Key Selling Points: | Long Service Life |

Product Description

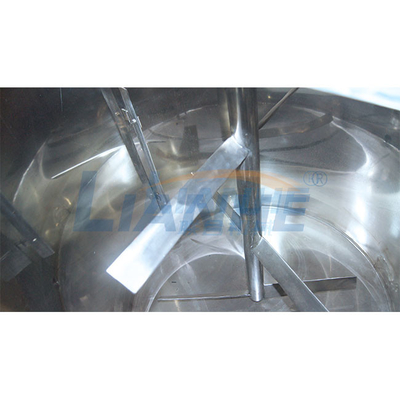

Single - Layer Stainless Steel Mixer Liquid Soap Lotion Blending Tank

Product Description:

This liquid mixer machine is mainly suitable for manufacturing liquid products. It can be equipped with the functions of mixing, dispersing, heating and cooling, etc. We can customize corresponding equipment for customers from different industries to improve their production quality. It is applicable for various industries, such as pharmaceuticals, chemical, cosmetic, daily care and food industry, etc.

You can customize its size to suit large, medium and small production, and you can also customize a complete set of production lines. In addition, we can design the machine according to the drawings you provide, or design the drawings and machines according to your specific requirements.

Product Application:

This machine is applicable in cosmetic, daily chemical, food, pharmaceutical, agricultural industries such as shampoo, hand sanitizer, liquid soap, detergent, disinfectant, beverage, fruit juice, mayonnaise, body cream, pesticide, fertilizer, chemical liquid, etc. products.

![]()

Dear all, thank you for visiting our web. Hope you can find what you need here. For a more efficient communication, please refer to the following question when sending the inquiry:

- What is your product? (liquid soap, or shampoo or ?)

- What is the capacity you need?

- Is your product highly corrosive?

- Does the product needs heating when mixing?

Product Parameters:

|

Model |

Capacity (L) |

Agitator |

Homiogenizer |

Heating system |

|||

|

power (kw) |

speed (rpm) |

power (kw) |

speed (rpm) |

Electric heating (kw) |

Steam heating (Mpa) |

||

|

PMC-50 |

50 |

0.75 |

0-65 |

3 |

3000 |

6 |

Steam heating energy conservation and environmental protection, selected according to need |

|

PMC-100 |

100 |

1.5 |

0-65 |

4 |

3000 |

9 |

|

|

PMC-150 |

150 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-200 |

200 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-300 |

300 |

1.5 |

0-65 |

5.5 |

3000 |

18 |

|

|

PMC-500 |

500 |

2.2 |

0-65 |

7.5 |

3000 |

27 |

|

|

PMC-1000 |

1000 |

4 |

0-65 |

11 |

3000 |

36 |

|

|

PMC-1500 |

1500 |

5.5 |

0-65 |

15 |

3000 |

45 |

|

|

PMC-2000 |

2000 |

7.5 |

0-65 |

15 |

3000 |

recommend steam heating |

|

|

PMC-3000 |

3000 |

11 |

0-65 |

15 |

3000 |

||

|

PMC-5000 |

5000 |

11 |

0-65 |

22 |

3000 |

||

|

The parameters for reference only, all the machines can be customized accordingly. |

|||||||

Product Features:

1. The mixing tank is made of all stainless steel materials. Its inner wall is made of high-quality 316L stainless steel (The part in contact with the material). The tank and pipe are mirror polished. Complying with GMP requirements and specifications.

2. The equipment consists of a stainless steel electric control cabinet and a main pot. The whole machine has a compact structure and it is easy to operate.

3. You can configure heating pot and cooling pot separately according to actual requirements. The materials can be heated or cooled according to process requirements. The heating method can be steam heating or electric heating.

4. There are various types of durable agitator blade, with strong mixing strength. It is suitable for the production of different products.

Product Details:

1.Motor brand: Siemens or ABB

2. Material: SUS304&316L

3. Stirring method: wall-mounted stirring, with Teflon scraper

4. Control method: button control

5. Electrical components: Schneider, Siemens and other international brands

![]()

Our Servers:

As a professional mixing equipment manufacturer, we customize machines to meet customer needs. We can send our skilled engineers to the customer’s factory to install the machine correctly. We also provide a one-year warranty for all our machines and after-sales service.

Rich Experience: