Glass Stainless Steel Lab Scale Homogenizer , Rustproof Cosmetic Laboratory Equipment

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, SGS, TUV |

| Model Number: | LH-VME-G10 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, D/A, L/C |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Capacity: | 1L-5L (customizeable) | Material: | Glass + Stainless Steel 316L |

|---|---|---|---|

| Application: | Liquid, Cream, Paste, Ointment, Sauce, Etc. | Temperature: | 120℃ Max |

| Mixing: | 0-100RPM | Homogenizer: | 10000-28000RPM |

| Pressure: | 0 To 0.9 MPa | ||

| Highlight: | Glass Lab Scale Homogenizer,Stainless Steel Lab Scale Homogenizer,Rustproof Cosmetic Laboratory Equipment |

||

Product Description

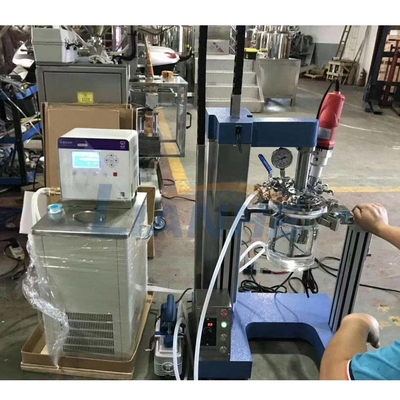

Glass Kettle Cosmetic Lab Equipment Homogenizer Mixer Emulsifier

Product Description:

Used for dispersing, mixing, emulsifying, homogenizing and dissolving in the laboratory. The reaction process of stirring, homogenizing, emulsifying, dispersing, mixing, etc. of the entire material can be observed through a glass kettle under vacuum or pressure conditions.

Applications:

- Production of cheeses, lotions, emulsions and fats in the pharmaceutical and cosmetic industries

- Mix solids such as calcium carbonate, talc, titanium oxide, etc. with the emulsion

- Blending additives and solid polymers with mineral oil

- Grinding and dispersing solids and fibers in liquids and polymers

Lab Vacuum Emulsification System Features:

Standard system processing capacity of 0.5L, 1L, 2L, 5L, 10L and other series, in a vacuum or pressure environment, to achieve the material dispersion, emulsification, homogenization, mixing and other processes. Can be equipped with a variety of efficient macro stirrer (optional), high-shear homogenization emulsifier (optional) and a reliable vacuum sealing system and temperature control system, a variety of sensing systems can simulate industrial production in the laboratory environment. It is the first choice for routine laboratory equipment, and meets all the simulation conditions of the complete equipment.

![]()

| 1.Foundation | 2. Glass kettle | 3. Scraping paddle |

| 4. Electric control cabinet | 5. Kettle clamp ring | 6. Kettle lid lock |

| 7. Temperature measuring probe | 8. Charge door | 9. Mixing motor |

| 10. Pillar elevator | 11. Driving wheel | 12. Lift cross arm |

| 13. Cauldron pillar | 14. The fall is expected to handle | 15. Vacuum unit |

| 16. Emulsion motor |

![]()

Application Area:

Dispersion, homogenization, emulsification, reaction, fermentation, cream preparation, macromolecular polymerization, synthesis reaction, etc.

Unique Features:

Ø Stainless steel sandwich thermostatic reactor

Ø The equipment is highly modular and can be equipped with various systems

Ø High speed motor imported from Germany, long life design, stable operation

Ø The design of the whole machine is reasonable, the materials are excellent, and the perfect emulsification system

Ø Stepless speed regulation, the maximum speed can reach 28000rpm, the maximum cutting line speed is 27m/s.

Ø Meet your different working environment (closed, open, normal pressure, vacuum)

Ø Overload protection, double protection insulation, safety for you

Ø Ø The work head is made of stainless steel and can be reused to meet GMP hygiene standards

Ø Equipment modular design, any system can be flexibly combined. Quick disassembly work head

Customer's Reviews:

![]()