LIANHE High Speed Cosmetic Lab Equipment Homogenizer 200-11000 Rpm

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-LM |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 10 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 60 Sets per Month |

|

Detail Information |

|||

| Material: | SUS304/316L | Application: | Liquid, Cosmetic, Daily Chemical |

|---|---|---|---|

| Key Selling Points: | Long Service Life, Wide Application | Weight: | 20 KG |

| Rate Torque: | 0.96n.M | Speed Range: | 200~11000 Rpm |

| Highlight: | LIANHE Cosmetic Lab Equipment,200 Rpm Cosmetic Lab Equipment,11000 Rpm High Speed Homogenizer |

||

Product Description

Cosmetic Lab Equipment High Shear High Speed Emulsifier Machine

Product Description:

The laboratory shear emulsifier is suitable for tissue dispersion in the biotechnology field, sample preparation in the pharmaceutical field, enzyme treatment in the food industry, and liquid and liquid phase, liquid and solid phase in the pharmaceutical industry, cosmetics industry, paint industry and petrochemical industry. Experimental aspects.

The experimental medium can be refined under the triple action of squeezing, strong impact and pressure loss expansion in the liquid, and they can be more uniformly mixed with each other to prevent or reduce stratification

It is an ideal instrument for crushing, emulsifying, homogenizing, polymerizing, suspending, dissolving and stirring etc.

Product Application:

Lab homogenizing emulsifier mixer machine is specially designed for laboratory application. It suits for biochemical, physicochemical, cosmetics, health care products, food etc. industry for liquid-liquid mixture & emulsification, or liquid-powder dispersion and emulsification. An ideal choice for scientific research institution.

Product Features:

1) Thedrive system is stable and reliable

2) The dispersing emulsifier with high shear effect

3) Can handle a wide range of viscosity

4) Stepless speed regulation

5) With five different specifications of the work head

6) Speed digital display

Product Packing List:

| Serial No. | Item | QTY | Serial No. | Item | QTY | |

| 1 | Emulsifying host | 1 | 6 | M5 wrench | 1 | |

| 2 | Base | 1 | 7 | The stator | 2 | |

| 3 | Supporting stand | 2 | 8 | Brusher(Spare) | 1 | |

| 4 | Beam | 1 | 9 | Product certification | 1 | |

| 5 | Supporting and fixing frame | 1 | 10 | Operation manual | 1 |

Product Advantages:

1. The operation state controller adopts stepless speed regulator, and the digital display type adopts touch structure, which is convenient for speed regulation and correct data.

2. The driving motor is a series micro motor with high output power and compact structure.

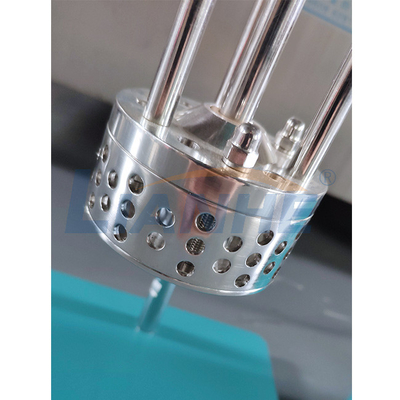

3. The shear emulsion mixing head is made of high-quality stainless steel, which has good corrosion resistance and is easy to be disassembled and replaced with stator.

4. The shear emulsified mixing head is connected with the driving motor by the coupling joint, and the operation is stable at high speed.

Homogenizer Head:

1. Stainless steel 304 or 316 material, corrosion resistance, high mixing efficiency, multi configuration stator to expand the application range.

2. Stator specification: 5mm2, 20mm2, 50mm2

Securing clip

Flexible securing clip, height adjustable.

Stainless steel rod

Rust resistant, easy to clean.

Technical data:

| Rated Power | AC 220V, 50 Hz |

| Power input | 510 W |

| Power output | 300 W |

| Rated Torsion | 0.96 N*m |

| Working period | continuous |

| Speed | 200~11000 rpm |

| Speed control | stepless |

| Speed indicator unit | 10 rpm |

| Max Capacity | 40000 ml (for water) |

| Homogenizer material | SUS304 L |

| Homogenizer diameter | Φ 70 mm |

| Homogenizer Torsion | 93 N*cm |

| Stator hole | 5 / 20 / 50 mm2 |

| Dimension | 360×260×760 mm |

| Working temperature | ≤ 40°C |

| Working Humidity | ≤ 90% |

Product Deatils:

Can change to different homogenizer head as you actual production needs:

![]()

![]()

E