Adhesive Sticker Bottle Labeling Machine 3000W Antirust Stainless Steel

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-AL |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 15 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Western Union, MoneyGram |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Applicable Size Of Label: | Customized | Material: | Stainless Steel |

|---|---|---|---|

| Key Selling Points: | Easy To Operate, Multifunctional | Warranty: | 1 Year |

| Label Accuracy:: | ±1mm | Suitable Bottle: | Round Flat Oval Bottle Square Bottle |

| Highlight: | Sticker Bottle Labeling Machine,3000W Bottle Labeling Machine,Antirust Adhesive Sticker Labeling Machine |

||

Product Description

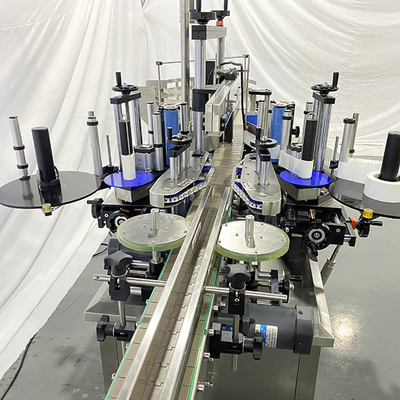

Automatic Multifunction Bottle Labeling Machine Adhesive Sticker Labeler

Product description:

Multifunctional labeling machine, one machine model is suitable for many different shape bottles like flat, round, oval, taper, etc. Fast speed and high accuracy operation.SIEMENS PLC control system make it easier to control.

If you only have round or flat bottles, we also have professional labeling machine for it. The price will be cheaper than the multifunctional type. Single face or double face are all no problem.

![]()

Working Process:

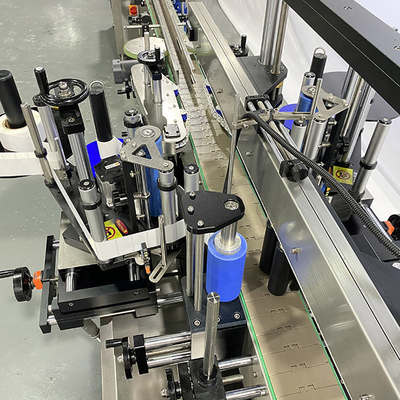

Core works: the product of bottle body separated, the sensor detects the product passes the signal returned to the labeling control system,the control system in place to control the motor sends label affixed to the product subject to labeling and position, product flow the standard unit cover,covered with standard rotation driven products, the label is roll coating, a label attached to the action is completed.

Product Feature:

1. Sticker Labeling Machine adopt mature PLC control system technology, make the whole machine stable

2. This type of Automatic Labeling Machine can be suitable for square /round/oval flat bottles at the same time, Of course client can choose to make one side or double sides labeling.

3. Use touch screen control system, record bottle date,

4. Conveyor with variable speed.

5. Synchronization chain mechanism, to ensure smooth and precise calibration,

6. Transparent sticker labeling without foam, adhesive sticker labeling without wrinkle,

7. Widely used and mutil-function with high flexibility,

8. Date/code printeris for optional,up to 3 lines, or you can choose inkjet printer.

9. Tranparent label sensor is for optional,

10. Can be customized according to your requirement,

11. Other match equipment: Automatic Cream Filling Machine, Automatic Capping Machine.

12. Powerful function, one machine can realize 4 products labeling(square, round, flat and dysmorphic bottle).

Product Parameters:

| No. | Item | Description |

| 1 | Label roll inner diameter | 76mm(customized) |

| 2 | Max Label roll outer diameter | 370mm(customized) |

| 3 | Label Height | 10-190mm(optional) |

| 4 | Labeling speed | 36/min(adjustable) |

| 5 | Material | Stainless steel 316&304 |

| 6 | Automatic Grade | Automatic |

| 7 | Driven type | Electric |

| 8 | Power Supply | 380V,50/60HZ,3000W |

Product advantages:

- The Double Sides Labeling Machine, provided with such mechanism as bottle Piloting, bottle dispensing and labeling, and counting etc,is most suitable for use of small amount of various products or for operation of single machine and single person. -- The labeling position, height and angle can be adjusted. It can be connected by conveying belt with the production line.

- With failure warning function, auto-counter technology, power saving function(the equipment will automatic turn to power saving holding state while no production in setting time),the production number setting hint function and parameters setting protection function(parameters have authority management)

Product details:

![]()

![]()

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte