Anticorrosive Vacuum Mixer Homogenizer

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE, TUV, SGS, GMP |

| Model Number: | PMC-500L |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 Set |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 30 Working Days |

| Payment Terms: | T/T, D/A, L/C |

| Supply Ability: | 20 Sets Per Month |

|

Detail Information |

|||

| Available Capacity: | 30L To 6000L | Tank Structure: | 3 Layers Of Steel, 2 Jacket |

|---|---|---|---|

| Material: | SUS316L/SUS304/SUS304 | Heating Method: | Electric Heating / Steam Heating |

| Cooling: | Water Cooling | Mixing Method: | One Way Or Two Way Mixing With Teflon Scraper |

| Mixing Speed: | 0-65RPM | Homogenizer Speed: | 3000RPM |

| Highlight: | Anticorrosive Vacuum Mixer Homogenizer,0.2 Mpa Vacuum Mixer Homogenizer,Durable Vacuum Emulsifier Homogenizer |

||

Product Description

500L Liquid Emulsifier Shampoo Mixer High Shear Lotion Heating Tank

Brief Introduction:

Total volume: 600L, Working volume: 500L; The volume of foam at the edge, which we did not count.

Shampoo mixing tank is widely used in such industries of coatings, pharmaceuticals, building materials, chemicals, pigments, resins, food, scientific research and etc. The equipment can be made of stainless steel 304 or 316L according to requirements of users' products, also heating and cooling devices are optional to meet different needs of production and process. Heating mode has two options of jacket electric heating and coil heating. The equipment has features of reasonable structure design, advanced technology and durable, simple operation and convenient use. It is an ideal processing equipment with less investment, quick operation and high profit.

Technical Parameter:

|

Model |

Capacity (L) |

Agitator |

Homiogenizer |

Heating system |

|||

|

power (kw) |

speed (rpm) |

power (kw) |

speed (rpm) |

Electric heating (kw) |

Steam heating (Mpa) |

||

|

PMC-50 |

50 |

0.75 |

0-65 |

3 |

3000 |

6 |

Steam heating energy conservation and environmental protection, selected according to need |

|

PMC-100 |

100 |

1.5 |

0-65 |

4 |

3000 |

9 |

|

|

PMC-150 |

150 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-200 |

200 |

1.5 |

0-65 |

4 |

3000 |

12 |

|

|

PMC-300 |

300 |

1.5 |

0-65 |

5.5 |

3000 |

18 |

|

|

PMC-500 |

500 |

2.2 |

0-65 |

7.5 |

3000 |

27 |

|

|

PMC-1000 |

1000 |

4 |

0-65 |

11 |

3000 |

36 |

|

|

PMC-1500 |

1500 |

5.5 |

0-65 |

15 |

3000 |

45 |

|

|

PMC-2000 |

2000 |

7.5 |

0-65 |

15 |

3000 |

recommend steam heating |

|

|

PMC-3000 |

3000 |

11 |

0-65 |

15 |

3000 |

||

|

PMC-5000 |

5000 |

11 |

0-65 |

22 |

3000 |

||

|

The parameters for reference only, all the machines can be customized accordingly. |

|||||||

![]()

Application Product:

Professional machine for produce shampoo, liquid detergent, perfume about medicine,cosmetic, daily chemical, pharmacy,foodstuff etc.

It is applied to reaction agitating of liquid scrubbing, textile assistant, medicine chemistry, food, beverage, perfume, perfumery compound, etc.It also applied to the products of homogenization, emulsifying, particle dispersion, etc.

![]()

![]()

Features:

1. Blending system adopts single-direction or double-direction wall scraping blending to satisfy different technological requirement.

2.Made of imported SUS304 or SUS316L stainless steel. The tank body and pipe are subjected to mirror polishing.

3.Material can be heated or cooled according to your formula (technological requirements)

4. Electric heating or steam heating.

5.Various forms of blending vanes are suitable for production of different types of products.

6.The stainless steel electric control cabinet can completely supervise the operation of equipment, and display such data as temperature and blending rotation speed, etc.

Due to the different production process requirements of users, the agitator can be configured in various forms such as paddle type, anchor type, frame type, and spiral type.

Customer's Reviews:

![]()

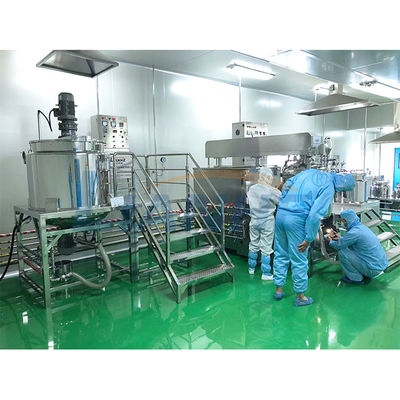

Exhibition & Project Cases:

![]()

C