PLC Plastic Tube Filling And Sealing Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-FS |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 20 working days |

| Payment Terms: | T/T, L/C, D/A, D/P, Cash |

| Supply Ability: | 30 Sets per Month |

|

Detail Information |

|||

| Material: | SUS304/316L | Filling Range: | 5-150m; 25-250ml; 30-500ml, Etc, Customized |

|---|---|---|---|

| Tube Length: | 50-210 Mm | Batch Printing: | Available |

| Key Selling Points: | High-Accuracy | Function: | Automatic Positioning, Filling, Heating, Sealing |

| Highlight: | PLC Plastic Tube Filling And Sealing Machine,Rustproof Plastic Tube Filling And Sealing Machine,Stable Semi Automatic Tube Sealing Machine |

||

Product Description

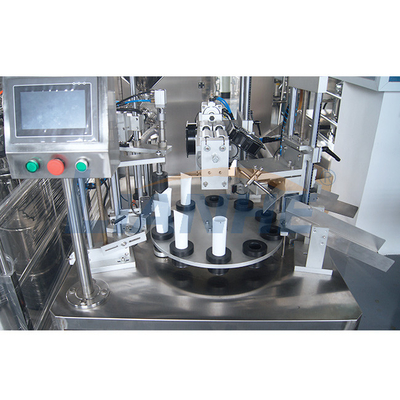

Semi Automatic Cream Toothpaste Tube Filling Machine Sealing For Plastic Tube

Product Description:

This machine is mainly used for composite hose, plastic tube is a quantitative filling, packing container materialand sealing, this machine is w idely used in pharmaceutical, chemical, food, chemical and other industries packaging. Such as cream, skin cream, toothpaste, shoe polish, glue, AB glue, epoxy glue, hair coloring agent, etc., liquid or cream filling and sealing.

Product Parameters:

|

Filling volume |

5-250ml(tube) |

|

Filling accuracy |

≤±1% |

|

Capacity |

40 tubes/min(normal type); 60-70 tubes/min(high speed type) |

|

Tube diameter |

OD10-50mm |

|

Tube length |

210mm(Max. length) |

|

Hopper volume |

40L |

|

Power |

220V/380V, can be customized |

|

Air pressure |

1.1KW |

|

Equipped motor |

0.5-0.7Mpa |

|

Air feeding |

0.37KW |

|

Convulsions |

0.37KW |

|

Hot air |

3KW |

|

Dimension |

3KW |

|

Weight |

1800kg (approx) |

Product Application:

The tube filling and sealing machine is suitable for automatic color code aligning, filling, sealing, date printing and end cutting of various plastic tubes and aluminum composite tubes. It is widely applied in daily chemical industry, medicine, food, etc.

Product Advantages:

1. Easy to operate and maintain.

2.Automatic positioning, filling, welding, cutting and trimming, printing code in one time.

3.. Stainless steel machine body, strong and beautiful looks,

4. Sealing mould can be customized according to customer requirements. Can seal many size of tubes.

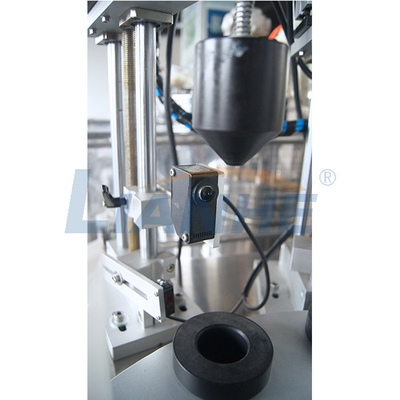

6. Ultrasonic Sealing Machine power source for the pneumatic, working steady, not easy to damage, customers can rest assured use.

7. Ultrasonic frequency can meet international standard, no harmful to human being or environment

8. Can be work in time, not need wait the heat time .

Product Features:

1.It adopts Ultrasonic sealing machine , good for difference products, Such as food, medical, cosmetic products. It will not hurting the products.

2. Overload protection, phase separation protection, power-fail protection.

3. Large Ultrasonic output power to ensure the sealing quality of various tube size and material.

4. With tube end trimming

5. Easy change working mold for difference tube diameter

6. Adjustable tube length

7. Machine include a gear pump filler( Good filling precision+- 1)

Product Details:

![]()

Our Servers:

We provide Turn-key project service to customer.

1. Factory Layout design;

2. Factory Decoration based on GMP standard;

3. Formula of products;

4. Raw material etc;

5. Machine design, whole production line from A to Z;

6. Shipping service, FOB, CFR, CIF etc;

7. Installation service. Training service, Mainte