SUS316L Cosmetic Cream Making Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME-B5 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Negotiable |

| Packaging Details: | Plywood Case / Bubble Film Packaging |

| Delivery Time: | 30 Working Days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Sets Per Month |

|

Detail Information |

|||

| Design Capacity: | 6.3L | Working Capacity: | 5L |

|---|---|---|---|

| Available Capacity: | 5L To 6000L Customizable | Mixing Speed: | 0-65RPM |

| Homogenizer Speed: | 0-3600RPM | Heating System: | 3kw Electric Heating |

| Cooling System: | Available | Vacuum System: | -0.1MPa |

| Highlight: | SUS316L Cosmetic Cream Making Machine,Steam Cosmetic Cream Making Machine,5L Cosmetic Mixer Machine |

||

Product Description

Lab - use 5L Vacuum Emulsifier Mixer Cream Emulsifying Machine

Brief Introduction:

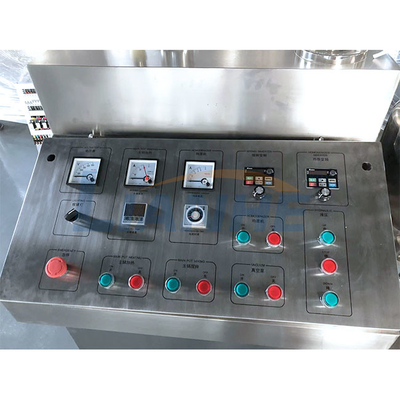

The vacuum emulsifier mixer mainly consists of water tank, oil tank, emulsifying tank (main tank), vacuum system, hydraulic lifting system (optional), button or PLC control system, operation platform, etc.

The machine is widely used in Cosmetic, Daily Chemical, Food and Pharmaceutical area for manufacturing viscous and none-viscous liquid products, such as cream, paste, sanitizer gel, body lotion, hair dye, ointment, sauce, mayonnaise, etc.

Featured by easy operation, stable performance, good homogenizing performance, high productivity, easy cleaning, reasonable structure, space saving, etc.

Technical Parameter:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters are for reference only, all the machines can be customized according to your needs. | ||||||||

![]()

Application Product:

- Skin & Hair Care: Body lotion, facial cream, sunscree cream, serum, hair dye, hair conditioner, etc.

- Cosmetic: Liquid foundation, BB cream, mascara, lipstick, concealer, lip gloss, etc.

- Pharmaceutical: Ointment, erythromycin eye ointment, Compound Dexamethasone Acetate, etc.

- Food: Mayonnaise, ketchup, cheese, sauce, paste, coconut oil, etc.

![]()

Performances And Features:

- The vacuum emulsifiers produced by our company include many varieties. The homogenizing systems include top homogenizer, bottom homogenizer, internal and external circulating homogenizer. The mixing systems include single-way mixing, two-way mixing and helical ribbon mixing. The lifting systems include single -cylinder lifting and double-cylinder lifting. Various high quality products can be customized according to customer's requirements.

- The triple mixing adopts the imported frequency converter for speed adjusment, which can meet different technological demands.

- The homogenizing structure made through German technology adopts the improted double-end mechanical seal effect. The maximum emulsifying rotation speed can reach 4,200rpm and highest shearing fineness can reach 0.2-5μm.

- The vacuum defoaming can make the materials meet the requirement of being aseptic. The vacuum material sucking is adopted, and especially for the powder materials, vacuum sucking can avoid powder floating.

- The emulsifying pot lid can adopt lifting system, easy to clean and the cleaning effect is more abvious, the emulsifying pot can adopt tilt discharge.

- The pot body is welded by imported three-layer stainless steel plate. The tank body and pipes adopt mirror polishing, which fully meet the international standards.

- All material contact parts are made of SUS316L, which can meet the manufacturing standard of cosmetic, pharmaceutical and food industries.

Machine Details:

![]()

![]()

![]()

Customer's Reviews:

![]()

Exhibition & Project Cases:

![]()

S