SGS Shampoo Manufacturing Machine

Product Details:

| Place of Origin: | China |

| Brand Name: | LIANHE |

| Certification: | CE , ISO , SGS , TUV |

| Model Number: | LH-VME200 |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1 |

|---|---|

| Price: | Contact Us |

| Packaging Details: | Normally packaged in wooden case or wrapping film, also can be customized |

| Delivery Time: | 30 working days |

| Payment Terms: | T/T, L/C, D/A |

| Supply Ability: | 20 Set/Sets per Month |

|

Detail Information |

|||

| Capacity: | 5L - 5000L Customized Avaiable | Control System: | Button Panel Or PLC Touch Screen Optional |

|---|---|---|---|

| Homogenizer Motor: | Siemens Or ABB Only | Homogenizer Speed: | 0-3600rpm |

| Stirring Speed: | 0-65rpm | Applicaiton: | Cosmetic, Food, Pharmaceutical Cream Or Paste |

| Highlight: | SGS Shampoo Manufacturing Machine,120 Degree Shampoo Manufacturing Machine,200L Equipment For Making Cosmetics |

||

Product Description

200L Vacuum Emulsifier Mixer Cosmetic Cream Vacuum Mixer Making Machine

product description:

Our vacuum homogeneous emulsification series equipment provides you with all the standard process-solutions, such as mixing, dispersion, agitation, homogenization and so on. Advanced mixing equipment ensures the uniformity of finished product quality. The vacuum emulsifier mixer has been designed to provide you with a variety of peripherals. Vacuum, jacket heating/cooling, hydraulic lifting, and sampling design make it ideal for fluid Integration.

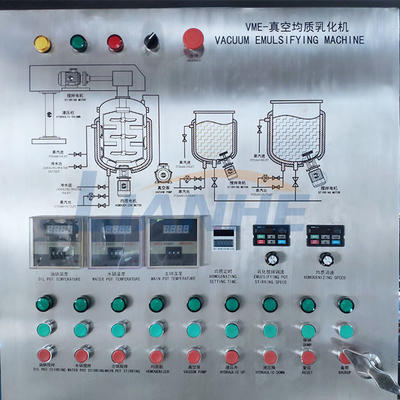

Control System:

Operators can manage the equipment by pressing buttons on the control panel, which include:

• Lighting Control System

• Main pot’s stirring operations

• Main pot’s uniform functioning

• Vacuum system’s operation control

• Water and oil pot’s mixing operations

• Heating process for water and oil pots

Product parameters:

| Capacity (L) | Homogenizer | Agitator | Vacuum pump | Heating system | ||||

| power (kw) | speed (rpm) | power (kw) | speed (rpm) | power (kw) | Limit vacuum | Electric heating (kw) | Steam heating (Mpa) | |

| 5 | 0.55 | 0-3600 | 0.4 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 10 | 1.1 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 6 | 0.2 |

| 20 | 1.5 | 0-3600 | 0.55 | 0-65 | 0.37 | -0.1 | 9 | 0.2 |

| 50 | 3 | 0-3600 | 0.75 | 0-65 | 0.75 | -0.1 | 12 | 0.2 |

| 100 | 4 | 0-3600 | 1.5 | 0-65 | 1.5 | -0.1 | 24 | 0.2 |

| 200 | 5.5 | 0-3600 | 1.5 | 0-65 | 2.2 | -0.1 | 28 | 0.2 |

| 300 | 7.5 | 0-3600 | 3 | 0-65 | 2.2 | -0.1 | 32 | 0.2 |

| 500 | 11 | 0-3600 | 4 | 0-65 | 4 | -0.1 | 50 | 0.2 |

| 1000 | 15 | 0-3600 | 5.5 | 0-65 | 4 | -0.1 | 54 | 0.2 |

| 2000 | 18.5 | 0-3600 | 7.5 | 0-65 | 5.5 | -0.1 | recommend steam heating | 0.2 |

| 5000 | 22.5 | 0-3600 | 15 | 0-65 | 7.5 | -0.1 | 0.2 | |

| The parameters for reference only, all the machines can be customized accordingly. | ||||||||

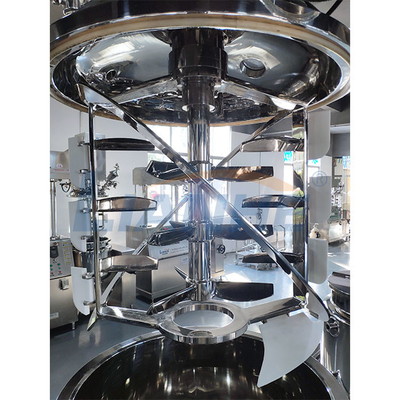

Product Structure:

The vacuum emulsifying mixer is consisting of the following elements:

• Control system for electrical components

• System for heating and temperature regulation

• Emulsifying pot with flip pot body and elevating pot lid

• Cooling system

• Vacuum Device

• Water pot

• Oil pot